In the textile and apparel industry, safe production is the lifeline for high-quality Industries development. In 2024, Handa Industries, with "Safety First" as its core development philosophy, will implement red line awareness throughout its entire production and operation process, strengthening safety defenses through systematic and refined management. By establishing a "full-staff, full-process, full-cycle" safety production management system, safety responsibilities at all levels will be clearly defined, forming a supervisory network with clear accountability and efficient coordination. Intelligent monitoring and risk warning systems will be used to strengthen on-site production control, establishing a closed-loop mechanism for hazard investigation and resolution ("Discovery-Rectification-Review") to ensure dynamic risk elimination. Furthermore, relying on regular safety training, practical emergency drills, and a digital assessment platform, Handa will continuously enhance the safety literacy and emergency response capabilities of all employees, laying a solid foundation for the company's stable development.

Improve safety committee

To strengthen its safety production defenses, Handa Industries has established a professional and international safety management system, with a Safety Committee at its core to oversee safety efforts both domestically and internationally. By 2024, based on the production characteristics of the textile and apparel industry and the demands of a globalized presence, the company will systematically optimize the Safety Committee structure, establishing a three-tiered management system comprised of "strategic decision-making - professional execution - local implementation."

High-level leadership and strengthened strategic coordination

The Safety Committee is led by senior corporate leaders, with members including senior executives from global operations, production and manufacturing, functional management and other departments. It is responsible for formulating global safety strategies, approving major safety investments and emergency plans, and ensuring the deep integration of safety management and corporate development strategies.

Professional empowerment to build a global management network

As the permanent executive body of the Handa Corporate Safety Committee, the Safety Assurance Department coordinates safety efforts both domestically and internationally, refining the committee's strategic plans into standardized implementation plans and formulating differentiated safety management rules tailored to the specific characteristics of domestic and international production bases. Through a combination of regular inspections, special oversight inspections, and unannounced checks, the department comprehensively monitors the implementation of safety measures. Furthermore, a safety management ledger is maintained at home and abroad to track the progress of rectifications in real time. Furthermore, customized safety solutions are provided to address regulatory and cultural differences in the countries where overseas bases are located. Online and offline training is provided to strengthen employee safety awareness and emergency response capabilities, ensuring the efficient implementation of the entire Industries safety management chain.

Implement locally and strengthen the main responsibility

Each branch has established a safety management department, directly led by the general manager, to strictly implement the annual goals set by the safety committee. This team includes workshop managers, safety specialists, and employee representatives, forming a comprehensive and comprehensive network of accountability. A tiered management system is implemented for high-risk areas in the textile and apparel industry, such as printing and dyeing chemical management and machinery safety, and regular targeted hazard inspections are conducted. Furthermore, a unified global safety incident reporting system has been established to ensure that overseas incidents are reported within two hours and a cross-border emergency response is initiated within 48 hours.

Mechanism innovation to improve management efficiency

The company implements a "three-dimensional" safety management mechanism: standardized management systems, digitalized inspection processes, and customized training systems. Through regular activities such as Safety Production Month and overseas safety training, the company fosters a safety culture that encourages full employee participation, building a solid safety barrier for its global operations.

Strengthening production safety management

Handa Industries has always prioritized production safety as its core development priority. Adhering to the principle of "safety first, prevention first, and comprehensive management," Handa Industries continuously strengthens its safety foundation through systematic management. By 2024, the company will establish a safety control network covering the entire industry chain through measures such as improving its production safety responsibility system, upgrading workplace safety standards, and strengthening safety management for all employees. This will achieve a dynamic zero-risk environment for both office and production sites.

During the reporting period, all of its production bases and subsidiaries at home and abroad maintained a record of "zero occurrence" of major production safety accidents, and its safety management performance continued to rank among the industry's leading levels.

Environmental Safety Management

Working environment safety assurance system

Handa Industries takes "employee health and safety first" as its principle and builds a full-process occupational safety protection network:

▶ Hardware facility upgrade: Each production base is equipped with a high-efficiency ventilation and cooling system to ensure that the air quality in dyeing, finishing, garment making and other workshops meets the standards; the Myanmar factory has set up a professional nursing station and water purification equipment, and simultaneously deployed standardized medical corners in each workshop, equipped with emergency medicine kits and first aid supplies.

▶ Standardization of protective equipment: Accurately equip protective equipment according to the risk level of the job:

REmployees in the dyeing and finishing workshop are equipped with insulating gloves, chemical-resistant masks, non-slip rubber shoes and other chemical-resistant equipment;

RGarment cutting and sewing positions are equipped with steel wire protective gloves, eye shields, etc. to reduce the hazards of mechanical operation and noise from the source.

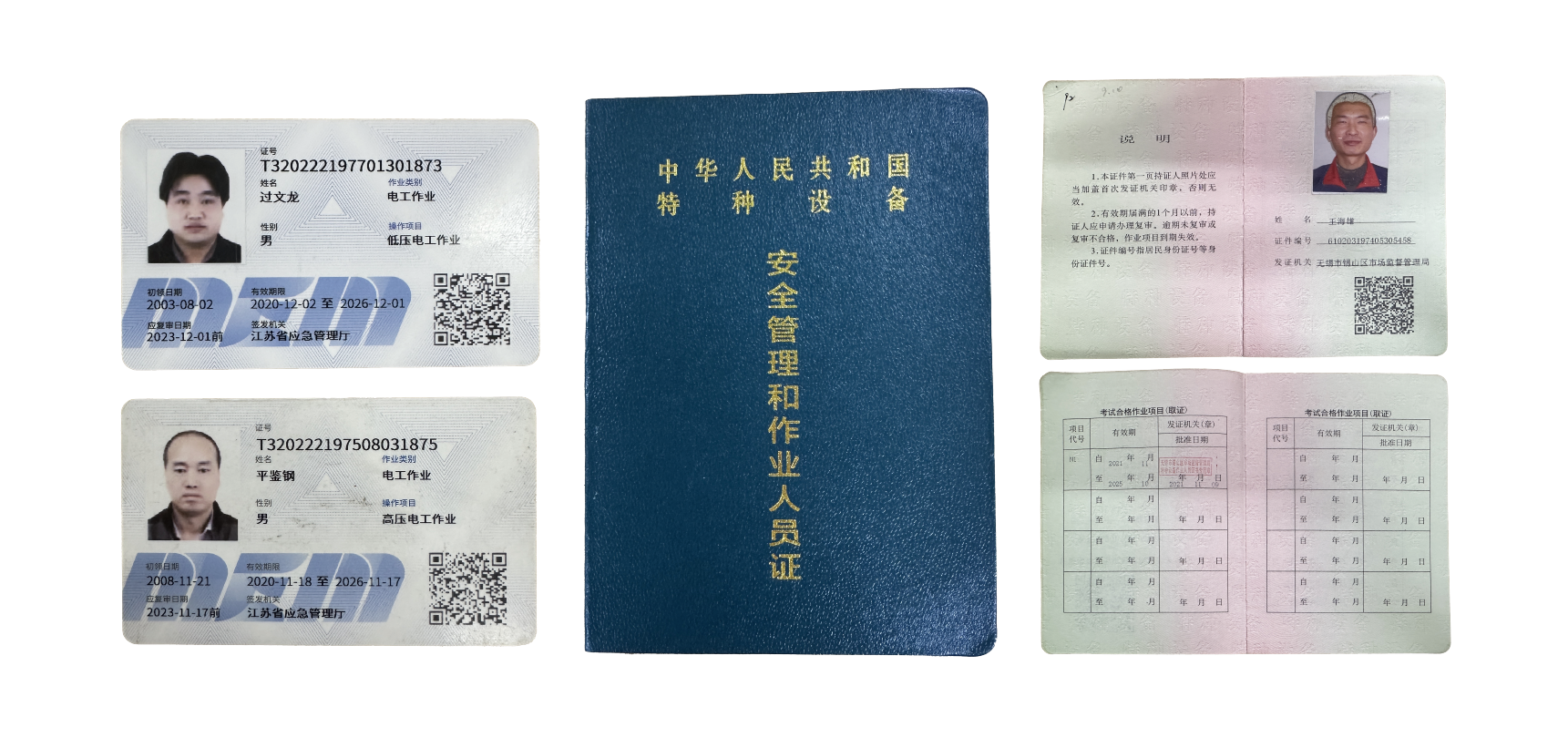

RCompliance management of special equipment: Special equipment such as boilers and pressure vessels strictly implement the national management and annual inspection system. Special workers such as electricians, forklift operators, and hazardous chemical custodians are 100% certified before they can take up their posts.

Occupational health and environmental risk management practices

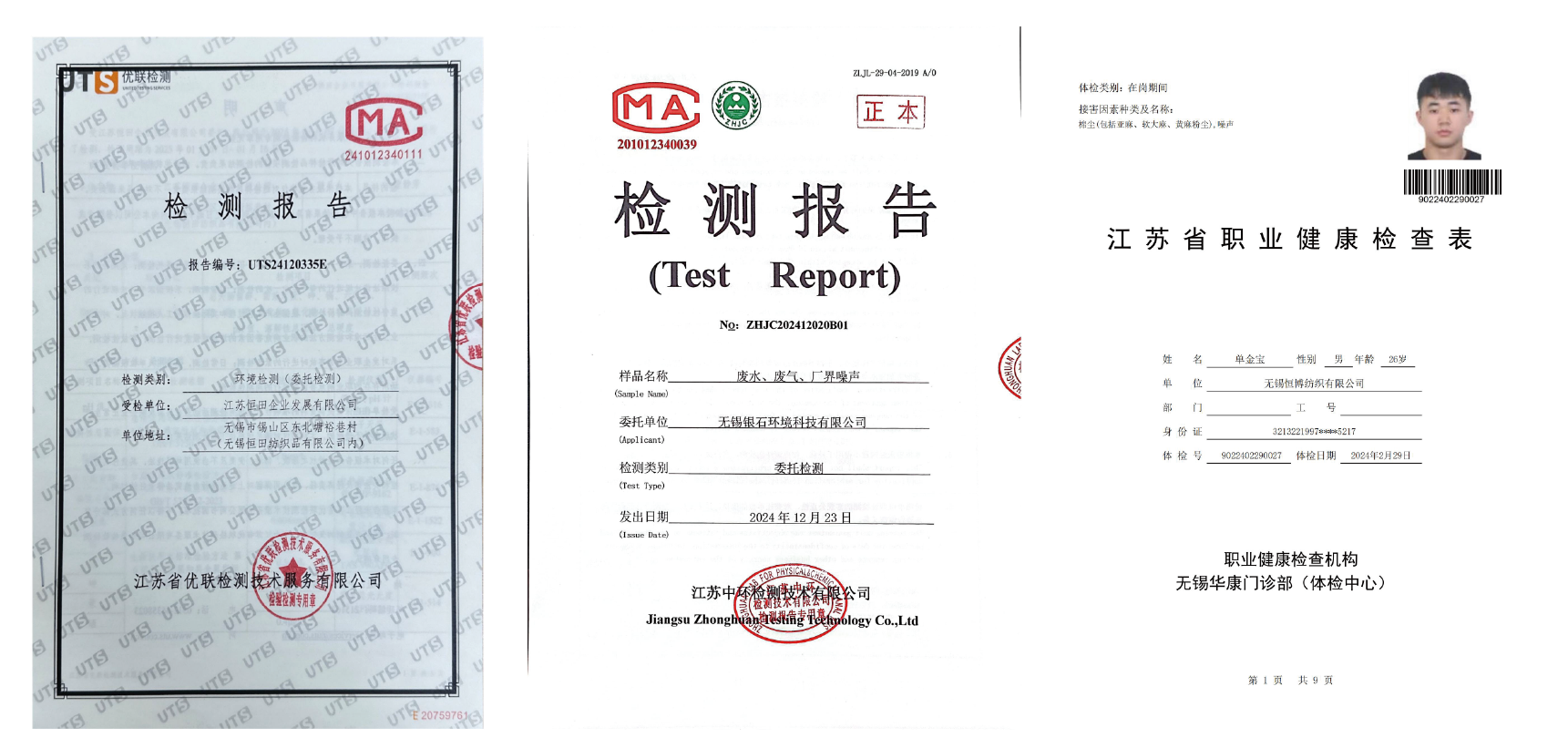

▶ Dynamic monitoring of hazard factors: We commissioned Guotong Testing Center to conduct annual testing of production areas. The results showed that:

RThe detection values of chemical harmful factors (dye volatiles, auxiliary agent residues, etc.) and physical factors (noise, light) all comply with the "Occupational Exposure Limits for Harmful Factors in the Workplace" standards.

RThe lighting intensity in the workplace meets the requirements of GB50034-2013 "Architectural Lighting Design Standard", ensuring safety and controllability in all scenarios.

▶ Water quality safety monitoring: We conduct regular testing of employees' drinking water sources and entrust a third-party agency to monitor water quality indicators. The results show that all parameters meet the requirements of the "National Drinking Water Quality Standard" (GB5749), ensuring drinking water safety.

▶ Compliance management of three waste discharges:

RWastewater testing: After treatment, the various indicators (COD, BOD, heavy metals, etc.) of the Industries's wastewater meet the requirements of the "Comprehensive Wastewater Discharge Standard" and the "Water Quality Standard for Wastewater Discharge into Urban Sewers", ensuring safe discharge into pipes;

RWaste gas testing: The company's production waste gas and living area waste gas emissions are in compliance with relevant standards. Among them, after treatment, the various indicators of the production waste gas meet the national and local emission standards, and the oil fume emissions in the living area meet the "Catering Industry Oil Fume Emission Standards." Overall waste gas emissions are compliant and controllable.

RFactory boundary noise detection: The factory boundary noise value complies with the corresponding functional area limit requirements of the "Environmental Noise Emission Standards for Factory Boundaries of Industrial Industries" and has no impact on the surrounding environment.

The company has obtained the pollutant discharge permit required by the state, and its three waste treatment facilities and monitoring capabilities meet the requirements of laws and regulations, and all test results are qualified.

▶ Occupational health examination mechanism: Occupational health examinations are carried out for typical positions in the company. The results of sampled employee examinations show that there are no occupational contraindications or suspected occupational diseases, confirming the safety of the working environment and production materials.

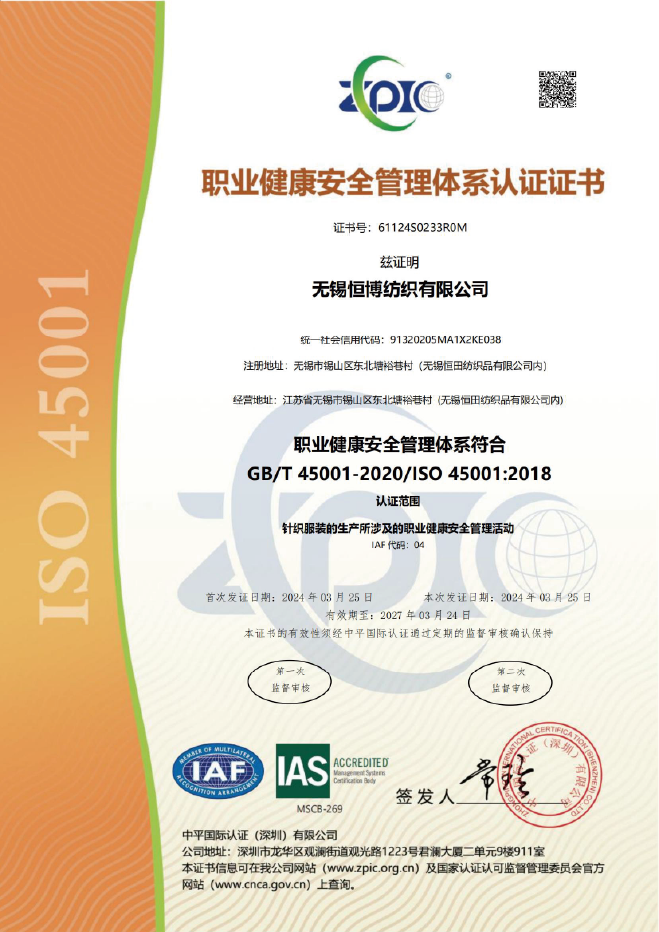

Passed occupational health and safety management system certification

Handa Industries successfully passed its occupational health and safety management system certification in March 2024, marking a significant breakthrough in the systematic and standardized development of employee occupational health and safety management. This certification is an authoritative affirmation of the company's long-term efforts in risk prevention and control, workplace optimization, and employee health protection, and demonstrates its "safety first, prevention first" management philosophy.

Environmental Material Management and Compliance

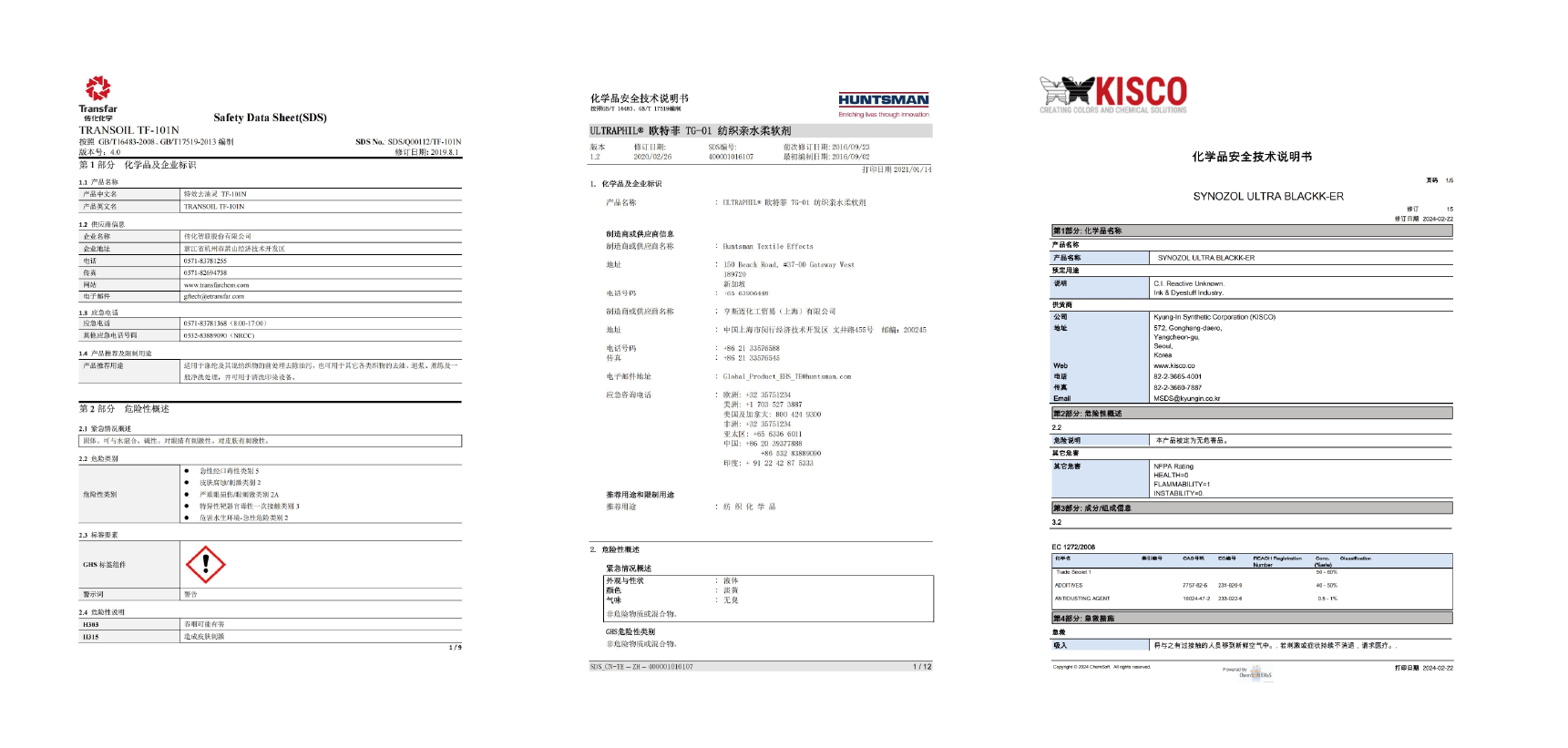

All dyes and auxiliaries are equipped with MSDS (Material Safety Data Sheet) to control the safety of ingredients from the source of procurement; third-party testing and verification show that production materials meet environmental standards and have no risk of toxic substance release, ensuring employee safety and environmental friendliness.

Through the three-in-one mechanism of "hardware protection + dynamic monitoring + health management", Handa Industries has achieved full-chain coverage of occupational health and safety management, building a safe and healthy working environment for employees while simultaneously consolidating the compliance foundation of green production.

Chemical Management

The company implements whole-process management of chemical procurement, transportation, storage, use and disposal, establish a "Chemical Hazardous Materials Management System" and a "Chemical Control Procedure", clarify the responsibilities of relevant departments, strengthen the construction of the chemical hazardous materials system, effectively manage chemicals, and prevent their impact on the environment and safety.

Over the past four years, Industries have improved their emergency response plans for hazardous chemicals based on actual conditions, identified potential accident hazards, emergency situations, and possible adverse effects and losses in the course of corporate activities, products, or services, and conducted emergency drills for hazardous chemical incidents to improve the scientific nature and effectiveness of emergency response plans, and further enhance the company's ability and level of handling emergencies.

The company insists on using safe and healthy chemicals and is committed to developing green and sustainable products. When purchasing, suppliers are required to provide MSDS Chemicals are strictly inspected upon arrival and stored according to their properties after passing the inspection. Professionals also conduct regular inspections of chemical sites. Through efficient chemical management and good process control, we reduce pollutant levels and work with stakeholders, including the supply chain, to minimize the impact of chemicals on the environment.

Cultivate a safe production culture

Handa Industries has established a safety education system oriented toward practical application and regularization, comprehensively promoting the development of safety capabilities among all employees. During this period, a series of activities were systematically implemented, including the "100-Day Safety Campaign," safety knowledge training (theoretical learning + written assessment), full-scenario emergency drills (emergency evacuation and firefighting exercises), on-the-job safety skills training, and on-site hazard inspections. This has formed a four-in-one education model of "learning, testing, practice, and inspection." By continuously strengthening the inculcation of a safety culture and consolidating skills, a fully engaged protective barrier for safe production has been established.

Regular safety skills and education training

The company regularly conducts safety training at its production bases both domestically and internationally. For example, its China Garment Division conducted training sessions themed "Everyone Talks About Safety, Everyone Knows Emergency Response." Through case analysis and cautionary education, the training strengthened employees' safety awareness and detailed workplace hazard prevention and control measures. The Myanmar Garment Division also conducted first responder training, where employees received systematic training from a professional medical team, mastered cardiopulmonary resuscitation (CPR) and trauma first aid, and were awarded certificates. The company promotes full employee participation through a combination of theory and practice, continuously deepening its safety training mechanism and strengthening the foundation of safe production.

Fire emergency response capability improvement drill

Handa Industries regards fire safety as a core control element of global operations, and has established a "standardized + localized" fire drill system at its production bases at home and abroad, forming an emergency response network covering China, Myanmar, Bangladesh, Egypt and other regions. Each base regularly conducts full-process fire drills, covering core links such as fire warning, emergency evacuation, initial fire fighting, and first aid for the wounded. By 2024, the global production bases have conducted a total of 10,000 fire drills, participating employees: More than 12,000 people, and strengthen the global fire safety line through practical exercises.

In the future, companies will adopt the management mindset of "safety is productivity" and continue to iterate the integration mechanism of "localized scenarios + standardized processes", so that every drill becomes a scale of safety awareness, and every skill becomes a brick and tile of the life line of defense, building a safety Great Wall with both humanistic warmth and technological hardness on the global manufacturing landscape.