Environmental Leadership

Handa Industries adopts "Green Handa" as its business strategy, adheres to the concept of "coexistence with the environment", and promotes green operations throughout the entire process: improving energy efficiency and reducing emissions through technological innovation, implementing strict environmental management throughout the product life cycle, continuously developing green processes and introducing environmentally friendly equipment, exploring and building a virtuous cycle model of "green production - ecological protection - industrial upgrading", and promoting the sustainable development of the textile industry through practical actions.

Strengthen environmental management

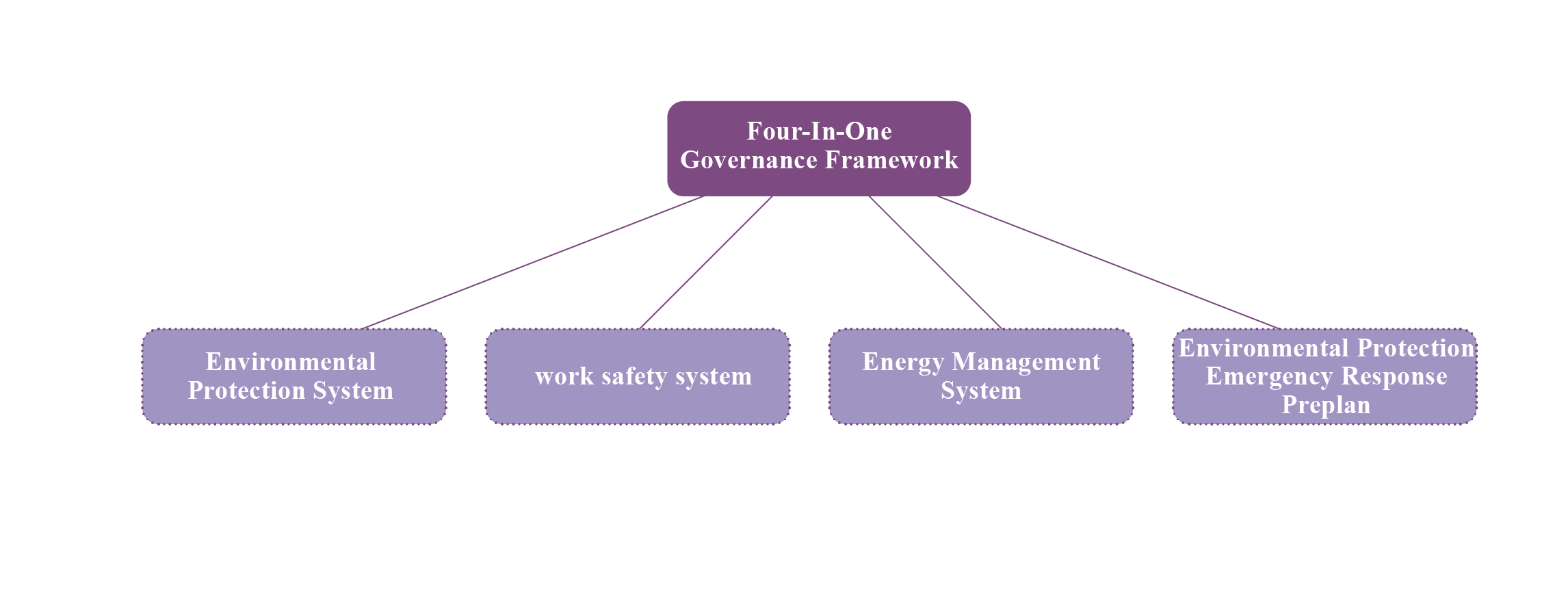

Handa Industries strictly adheres to national laws and regulations on ecological and environmental protection. With "upholding the ecological red line" as its core principle, it has established a multi-level, full-process environmental management system. The company deeply integrates its environmental protection system, production safety system, energy management system, and environmental protection emergency response plan to form a four-in-one governance framework. It has also established a cross-departmental environmental management department to achieve closed-loop management from strategic planning to implementation. By incorporating indicators such as environmental protection, energy consumption, and resource recycling into the management team's KPI assessment system, a management mechanism with "personalized responsibility and on-the-job assessment" has been established to ensure standardized operations across all production links and processes.

In terms of implementing environmental protection policies, Handa Industries has anchored its green development goals and built a comprehensive, multi-level environmental protection system. Through technological innovation and process optimization, it continuously improves energy efficiency and promotes refined energy management; actively explores new models of resource recycling, improves resource utilization, and reduces waste generation. At the same time, the company continuously strengthens its clean production level, controls pollution emissions from the source, and ensures that the entire production process is green and low-carbon. In addition, Handa improves its green manufacturing system, promotes the green and intelligent transformation of all aspects of production and manufacturing, promotes low-carbon development, and helps“Dual Carbon”To achieve the goal, the company also fostered a strong green development atmosphere through training, publicity, and cultural development to foster full employee participation, integrating environmental protection concepts into every detail of its operations.

All of the company's production bases have passed the ISO14001 environmental management system certification, building a management framework based on international standards and integrating core indicators such as safety control, energy conservation and consumption reduction, and waste reduction into daily operating processes.

During the year, the company achieved excellent results in energy conservation and emission reduction, environmental protection, clean production, safe production, and the circular economy. All pollution control facilities operated normally and met environmental protection requirements. There were no environmental pollution accidents, disputes, or environmental complaints, and the company received no administrative penalties or fines for violations of regulations or laws from environmental protection authorities.

Environmental risks identified by Handa Industriesin 2024

Type | Describe |

Wastewater pollution | Printing, dyeing, bleaching and other processes use dyes and auxiliaries. If the wastewater is not completely treated and discharged harmlessly, it will pollute the water body, endanger the ecosystem and human health. |

Exhaust gas pollution | • Dust spread during textile and garment processing affects air quality and employee respiratory health • Exhaust emissions from printing and dyeing machines and other equipment do not meet standards, causing air pollution |

Resource consumption | • Excessive use of water resources, especially in dyeing and printing factories • Regions with unstable power supply, such as Myanmar, rely on diesel power generation, increasing carbon emissions |

Chemical risks | • Toxic substances remain in the finished product, causing secondary pollution • Companies’ lax control over the use of chemicals such as additives |

In 2024, the company achieved significant results in environmental protection efforts, with all key environmental indicators passing audit and achieving full compliance. To continuously improve environmental management, the company systematically compiled documents such as the "Environmental Risk Assessment Report," "Emergency Plan for Environmental Emergencies," and "Water Resources Feasibility Report for Water Intake Projects." Furthermore, the company improved its "Safety Status Assessment Report," "Production Safety Accident Emergency Rescue Plan," and the "Three Simultaneous" occupational health management system, strengthening its overall environmental safety defenses.

The environmental performance of a printing and dyeing factory is a crucial cornerstone of a company's sustainable development and a key indicator of its core competitiveness. In the new era, Handa Printing and Dyeing Factory continues to increase its environmental protection investment. Relying on technological innovation and management optimization, it further promotes clean production, dynamically tracks progress towards environmental protection goals, and strives to build a green, low-carbon, and energy-efficient modern printing and dyeing factory.

Main environmental protection goals for printing and dyeing factories in 2024

Item Head | Index | Management plan (measures) | Progress or performance |

Sewage discharge complies with the urban sewage treatment takeover indicators | 1. Sewage treatment compliance rate 100% 2. COD≦200mg/L, total amountLess than 50 tons 3. Total sewage discharge: 1 millionless than tons | 1. Strengthen management and improve sewage treatment regulations and operating procedures 2. Standardize testing and control according to requirements 3. Equipped with sewage flow meter and online detection equipment | 1. Sewage treatment facilities and monitoring facilities are complete, with a normal operation rate of 100% and sewage discharge meeting 100% of the standards. 2. COD content does not exceed 200mg/L, and the final total discharge36.1ton 3. Total sewage discharge691496ton |

Preventing Chemical Spills | Safe storage and transportation without leakage | 1. Classify and store, and make labels 2. Employees are familiar with its performance characteristics and operate according to specifications 3. Take safety and leakage prevention measures during transportation | A chemical leakage emergency plan was developed and protective training was carried out. No chemical leakage accidents occurred during the year. |

General solid waste treatment | Comprehensive utilization rate 100% | 1. Waste additive barrels and waste packaging bags are recycled by suppliers 2. Domestic waste will be handled uniformly by the local community 3. Wastewater sludge is purchased by qualified environmental protection companies | All waste additive barrels and waste packaging bags are recycled by suppliers at the company, and the community regularly collects domestic garbage at the company; sludge is recycled by the environmental protection company and sent to the power plant for harmless incineration. |

Hazardous waste disposal | Processing rate 100% | Waste oil generated by the exhaust gas treatment of the setting machine Dye packaging bags | Purchased and processed by qualified waste oil treatment and hazardous waste qualification units |