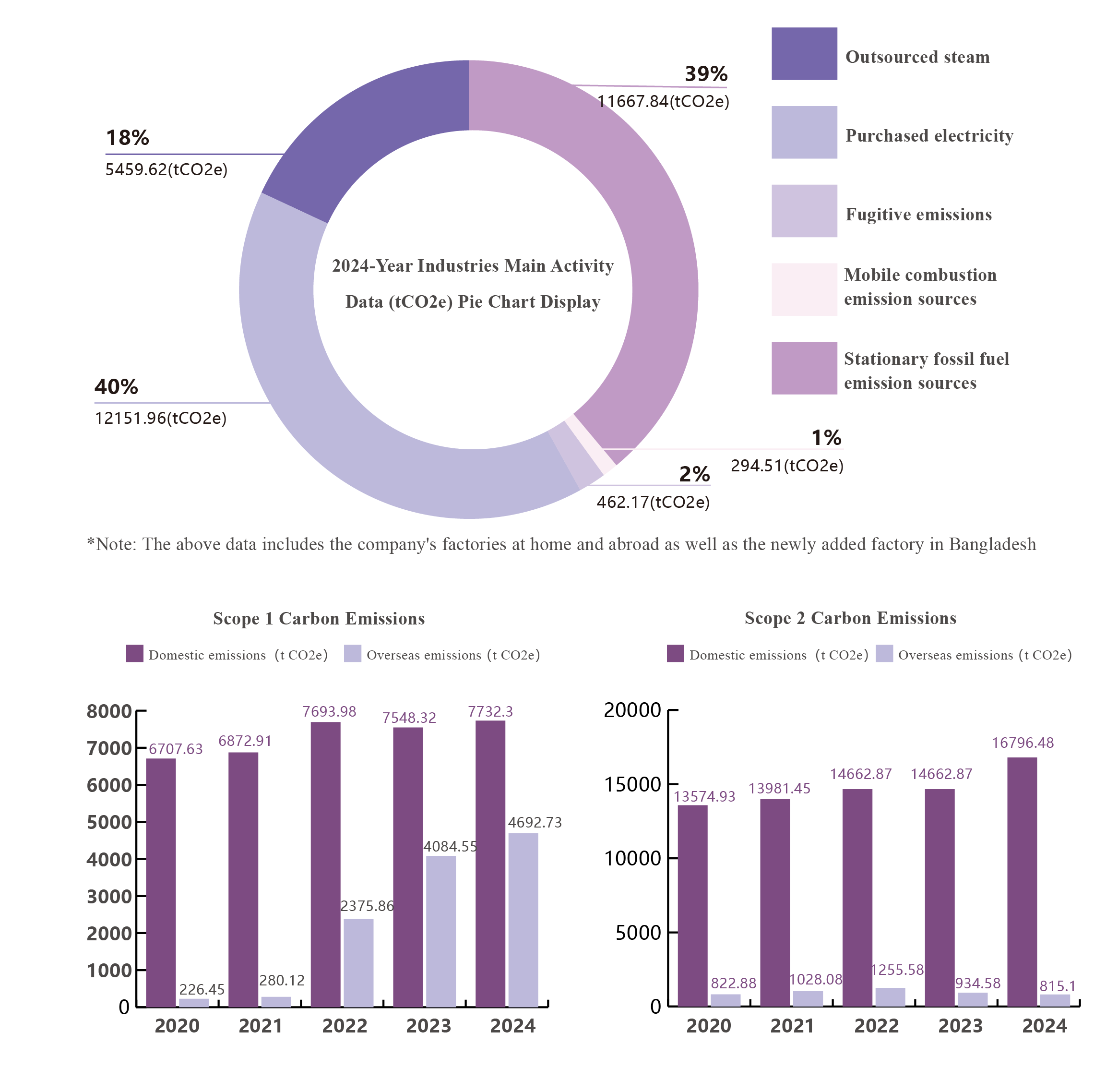

Handa Industries adheres to the "dual carbon" goal to lead green development, integrates the "dual carbon" concept into the entire process of sustainable development, and properly handles the relationship between corporate development and energy conservation and emission reduction.Taking 2017 as the base year, carbon emission data accounting work will be carried out for all the company's factories and sales departments at home and abroad.

After calculation, The total carbon emissions of Handa Group in the past four years are30036.61 tCO2e(Excluding Scope 3), of which domestic emissions are24528.78 tCO2e, overseas emissions were 5507.83 tCO2e.

Emission reduction actions

Reduce energy consumption in office and production processes, improve energy efficiency, and thus reduce carbon emissions.

•Electrification transformation of equipment;

• Identify energy conservation and emission reduction measures, including equipment insulation, steam usage efficiency, and efficiency optimization of the setting machine air compressor;

• Eliminate old and high-energy-consuming production equipment and introduce low-energy, low-power equipment;

• Use new energy vehicles (cars, trucks, etc.) as replacements for fuel vehicles;

•Adopting intelligent typesetting system to reduce fabric loss and increase fabric utilization rate to over 95%;

• Set up classified recycling points, and waste fabrics and yarns will be recycled by professional companies;

•Donate or sell obsolete equipment after repair to reduce resource waste.

Energy transition

Increase the proportion of green energy in its own energy structure and comprehensively supervise energy usage.

• In terms of distributed photovoltaic power generation systems, Handa Industries has established a multi-regional renewable energy utilization system. The distributed photovoltaic power station at the corporate headquarters campus generates 1.09 million kWh of electricity annually, with 930,000 kWh consumed locally, resulting in a self-consumption rate exceeding 85%. The photovoltaic power station at the printing and dyeing park generates 1.22 million kWh of electricity annually, with 100% of the generated electricity consumed. The Yunnan factory, connected to the regional photovoltaic grid, consumes 470,000 kWh of green electricity annually. By generating and consuming energy locally, this system effectively reduces dependence on traditional energy, improves energy self-sufficiency and clean energy, and provides solid support for the company's green transformation of its energy structure.

•In the process of upgrading its energy management system, Handa Industries has built an intelligent and visual energy management platform based on the Internet of Things, big data and artificial intelligence technologies.

Obtained energy management system certification

Handa Industries has successfully passed the Energy Management System Certification. This certification is a dual recognition of the company's energy management level and sustainable development strategy.

Since launching its energy management system, the company has strictly adhered to national standards and industry norms, established and improved its energy management system and processes, and strengthened its employees' awareness of energy conservation. Through certification, the company has optimized its energy management processes and increased energy efficiency, further shaping its image as a green Industries.

Won the "Green Factory" certification at both the municipal and provincial levels

Handa Industries has been awarded the title of "Green Factory" by both Wuxi City and Jiangsu Province. The company consistently adheres to the core concept of green development and incorporates it into every aspect of its production and operations, striving to promote sustainable development through technological innovation and industrial upgrading.

Selected into the "30・60 Carbon Neutrality Acceleration Plan" case collection

On May 30, Handa Industries made its debut at the "2024 Climate Innovation and Fashion Summit" in Beijing. The company's low-carbon "Home Office Series" was successfully selected for the "30・60 Carbon Neutrality Acceleration Plan Corporate Case Collection", and Chairman Han Chun was selected as a contributor to the progress manual.

This case study showcases the practices of 27 companies in five key areas, including carbon footprint measurement and zero-carbon product pilots, demonstrating their path from carbon reduction to long-term carbon management. Handa, with its "lean production + full-cycle improvement" model, has become a benchmark case study for the textile industry's implementation of the "30·60" goal, continuously promoting green transformation through technological innovation and social responsibility.

Water Resource Management

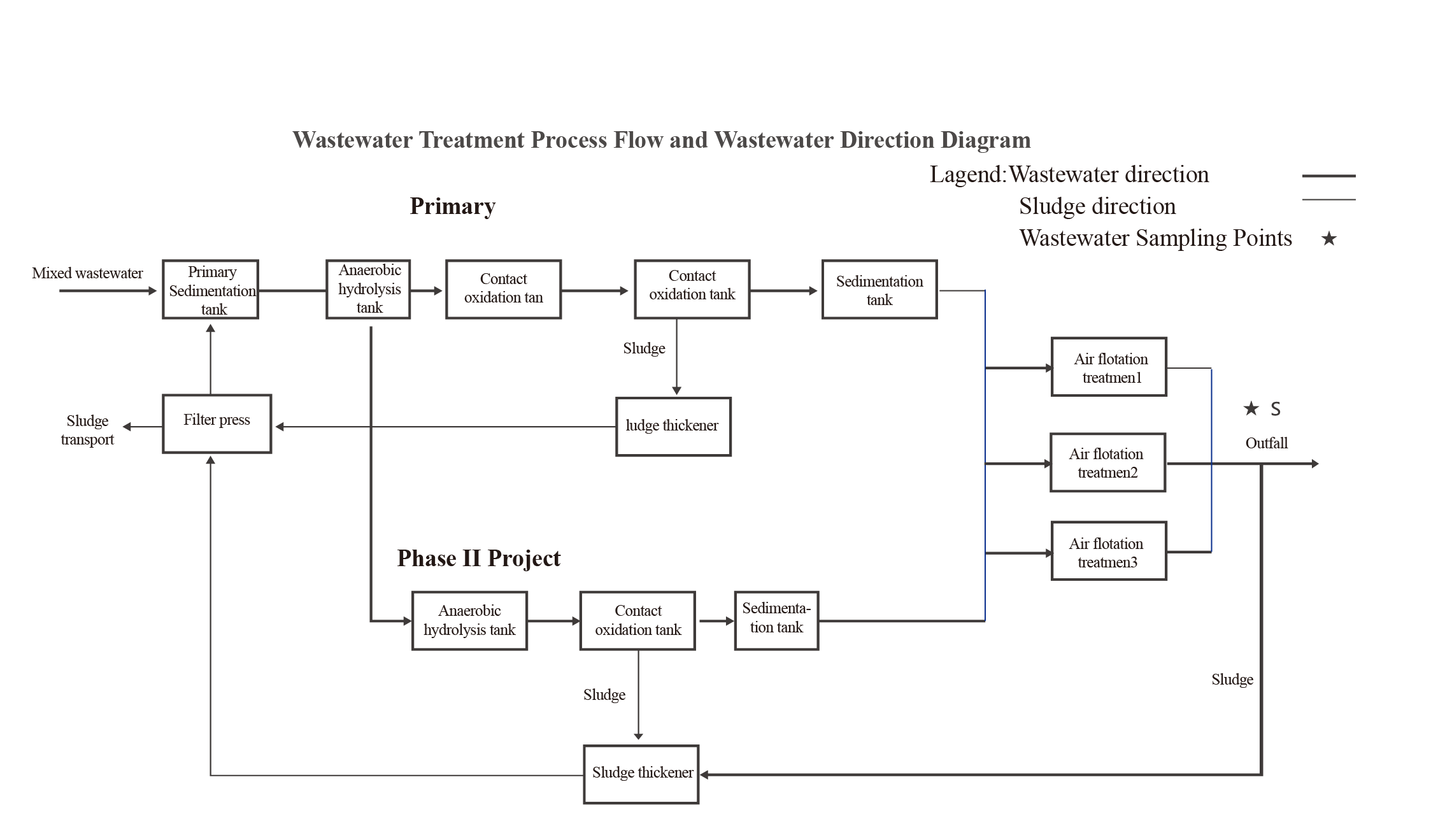

As a core component of the company's wastewater treatment, the printing and dyeing plant receives high attention and strict oversight from headquarters. Strictly adhering to environmental protection department requirements, the plant has established an intelligent wastewater discharge monitoring system, equipped with online monitoring systems and flow meters. Professional maintenance and regular calibration are performed by a reputable third-party organization to ensure accurate and reliable data. By 2024, the stable operation rate of environmental protection facilities will reach over 99%, fully ensuring compliance with emission standards.

In addition, the company obtains national pollutant discharge permits in accordance with the law, strictly implements the pollutant discharge permit management system, and submits implementation reports on a regular basis to achieve compliance, standardization, and transparency of environmental management, and continuously improve the level of green production.

To strengthen environmental monitoring and governance, the company's printing and dyeing plant has established a wastewater treatment monitoring room to ensure strict control of the wastewater treatment process. At the same time, video surveillance systems are installed at key facilities such as sewage outlets to achieve round-the-clock, all-around monitoring.

Annual pollutant emissions

Pollutant name | 2022 | 2023 | 2024 | Increase/Decrease |

Sewage (tons) | 865960 | 786080 | 691496 | -12.03 |

COD (tons) | 43.29 | 39.3 | 36.1 | -8.14% |

Exhaust gas management

Waste gas treatment is a crucial step for businesses to achieve green and sustainable development. Handa Printing and Dyeing Factory has established a modern waste gas treatment system combining "intelligent monitoring and digital supervision." All waste gas treatment facilities are equipped with online automatic monitors and high-definition video surveillance systems, enabling real-time data transmission via a networked connection to an environmental monitoring platform, ensuring full traceability and verifiability of emissions.

The factory has also established a comprehensive equipment operation and maintenance management system. Through regular inspections, preventive maintenance, and professional upkeep, it ensures the stable and efficient operation of environmental protection facilities throughout the year, providing a solid guarantee for the company's green production.

-83789c9bf4be4d9abbc47edc589cd1a8.jpg)

In 2014, the total amount of condensed water, process cooling water, recycled water and reused water collected was 237,800 tons, accounting for 30.3% of the total water consumption.%. With 202Compared with the previous three years, the energy consumption per unit of output value has decreased by 1.61%.

In 2024, the total annual Industries pollution discharge fee is 4536970Yuan.

During the reporting period, the company had no environmental pollution accidents, received no complaints about environmental pollution, and was not subject to legal sanctions for violating relevant environmental laws and regulations.