Sustainable management capabilities

Global Responsible Operations

As a global textile and apparel company, we have always integrated sustainable development into our DNA, demonstrating our commitment to the global market through responsible operations. Through a manufacturing network spanning four continents and strict adherence to international ESG standards, we ensure that every product, from raw material sourcing to production and delivery, adheres to environmental friendliness and international business ethics.

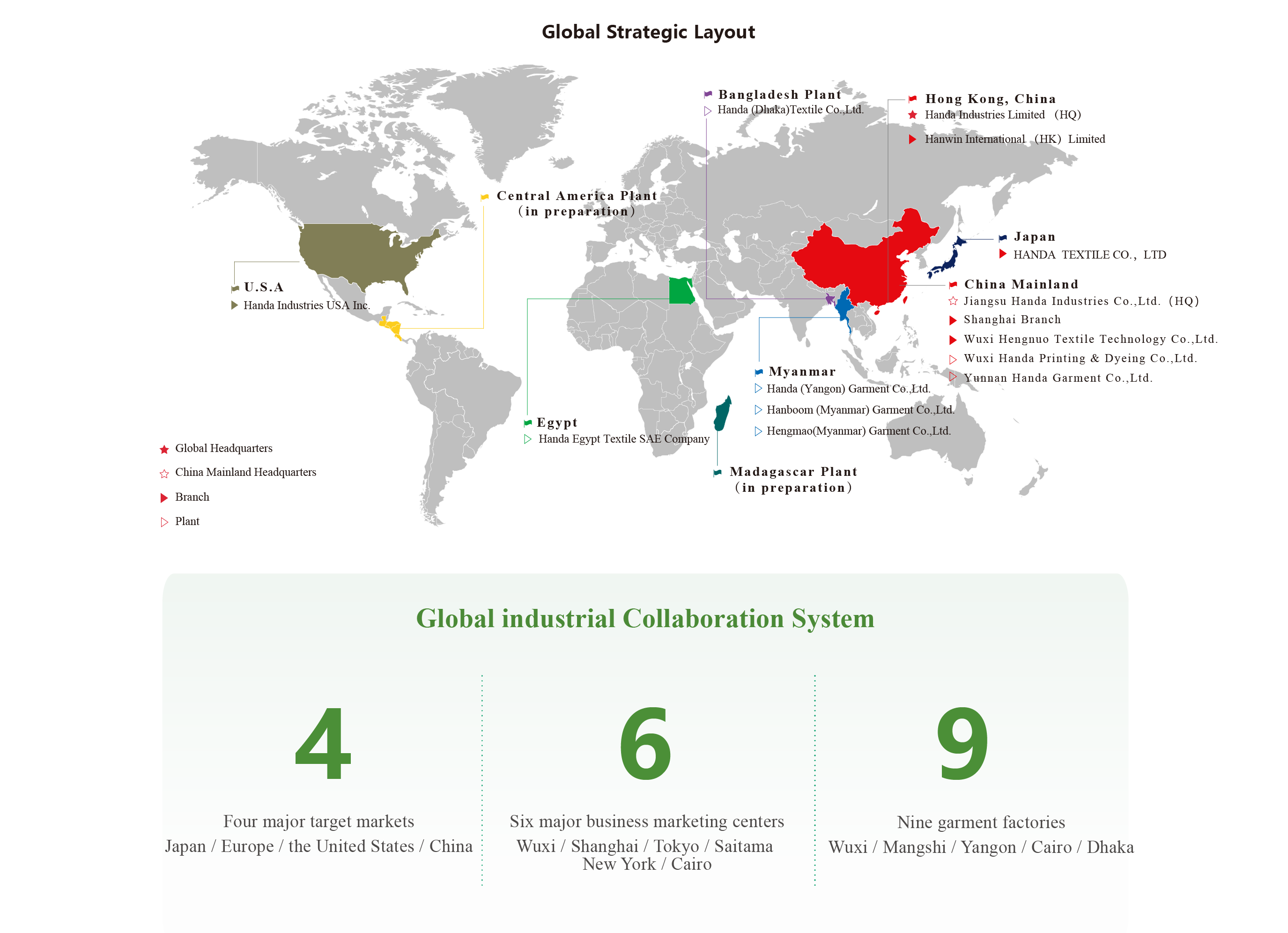

Global strategic layout

Through its global strategic layout, the company has established a three-dimensional "4+6+9" industrial collaboration system: Leveraging Hong Kong as a global capital and logistics management hub, the company has deepened its presence in four core markets: Japan, Europe, the United States, and China. Relying on six strategic operations centers: the Wuxi headquarters, Shanghai, Tokyo (Sendagaya and Saitama), Manhattan (New York), and Cairo (Egypt). Furthermore, based on corporate development and brand customer needs, the company has established nine manufacturing bases in key locations around the world—including the Wuxi headquarters factory, the Mangshi factory in Yunnan, the Yangon factory in Myanmar (four facilities), the Cairo factory in Egypt (two facilities), and the Dhaka factory in Bangladesh. This layout not only ensures the precise alignment of global production resources with market demand but also forms a complete closed-loop value chain from innovation and R&D to end-user delivery, demonstrating the strategic depth and rapid responsiveness of the group's global operations.

Production Base Overview

Wuxi, China (Mainland Headquarters)

Handa Industrial Park

▌Geographical coordinates: Dongbeitang Town, Xishan District, Wuxi City, Jiangsu Province

Strategic Positioning:

✓ Functional knitted fabric product development base of China National Textile and Apparel Council

✓ National Functional Knitted Fabric Trend Research Center

✓ China Textile Industry Industrial Design Center

▌Core Industries:

Jiangsu Handa Industries Development Co., Ltd.

Wuxi Hengnuo Textile Technology Co., Ltd.

▌Park size: 75,600 square meters of modern industrial park

Core features:

✓ Product Innovation and R&D Center ✓ Fashion Design Center ✓ Supply Chain Management Headquarters

✓ Digital Transformation Operations Center ✓ Global Production Operations Hub ✓ Smart Garment Manufacturing Center

Printing and Dyeing Park

▌Geographical coordinates: No. 188, Dongbeitang Nongxin Road, Xishan District, Wuxi City, Jiangsu Province

▌Professional field: dyeing and finishing of high-end knitted fabrics

▌Operating entity: Wuxi Handa Printing and Dyeing Co., Ltd.

▌Park size: 33,000 square meters of professional dyeing and finishing factories

Technical Features:

✓Clean production process✓Digital color management system✓ Flexible production configuration

Weaving Park

▌Geographical coordinates: No. 8, Jingda South Road, Xibei Town, Xishan District, Wuxi City, Jiangsu Province

▌Industry Focus: Large-Scale Production of Weft Knitted Fabrics

▌Operating entity: Hengnuo Weaving Factory

▌Park size: 48,848㎡ automated weaving park

▌Productivity advantage:

✓Annual output exceeds 4,000 tons of high-end knitted fabrics

✓ Equipment includesItaly and Taiwan, etc.A total of 120 advanced looms

✓ Expert in the research and development of quick-drying thin and other functional fabrics

Yunnan, China

Yunnan Production Base

▌Geographical coordinates: Qiangyuan Road, Mangshi Industrial Park, Dehong Prefecture, Yunnan ProvinceNo. 7

▌Base size: 2,700 square meters of garment production factory

Core Positioning:

✓ A strategic production base radiating to the Southeast Asian market

✓ Intelligent clothing manufacturing

▌Production Features:

✓ Equipped with automatic cutting machines and other automation equipment

✓ Apply MES and other digital systems to achieve full production process control

-59a96ce8aba24557b9036c30b4e48cf3.jpg)

Yangon, Myanmar

Myanmar production base

Myanmar Garment Factory No. 1

▌Coordinates: No. 288, Hebian Road, Shuilinban Industrial Zone, Hlaingdaya City

▌Scale: 11,000㎡ factory, 25 assembly lines

▌Production capacity: Average monthly output of 1.3 million pieces

Myanmar Garment Factory No. 2

▌Coordinates: No. 13-15, the junction of Wushuibin Road and Wumu Road, Shuilingban Industrial Zone

▌Scale: 42,000 square meters of factory buildings, 73 production lines

▌Production capacity: Average monthly output 3.5 million pieces

Myanmar Garment Factory No. 3

▌Coordinates: No. 480, Wumasuwen Road, Shuilingban Industrial Zone

▌Scale: 16,000㎡ factory, 41 production lines

▌Production capacity: Average monthly output 2.1 million pieces

Myanmar Garment Factory No. 5 (new factory to be built in 2024)

▌Coordinates: No. 484, Vamasuoongdao Road, Shuilingban Industrial Park

▌Scale: 12,000㎡ factory,20production lines

▌Production capacity: Average monthly output of 200,000 pieces (woven products)

▌Supporting system: Professional printing and embroidery factory

▌Comprehensive advantages:

✓ Covering all-round production of knitting and weaving

✓ Nearly 7,000 skilled employees, China and Myanmar collaborate to achieve efficient operations

✓ Deep localization, highly recognized by local governments and communities

✓ Rich management experience and mature management processes

Egypt, Africa

Egypt production base

▌Geographical coordinates: Aviation College Road, Bilbais, Egypt

▌Base size:

✓ Egypt's first garment factory covering 35,000 square meters

✓ Egypt's second factory, a 53,000㎡ garment factory

▌Productivity advantage:

✓ A factory in Egypt has 47 garment production lines with a monthly production capacity of 1.8 million pieces

✓ Egypt's second factory has 60 garment production lines with a monthly production capacity of 2.3 million pieces

✓ Planning supporting fabric factories

✓ Duty-free in Europe, Türkiye and the United States

Bengal

Bangladesh production base

▌Geographic coordinates:Savar District, Dhaka Province, Bangladesh

▌Base size:10,000㎡Garment Factory

Capacity Planning:

✓ Current configuration: 18stripready-to-wearproduction line, monthly production capacity of 800,000 pieces

✓ strategyPlan: Expand garment production lines to nearly 300 and build a fabric factory