Sustainable product innovation

In a rapidly changing market environment, if Handa Industries wants to maintain its lead amidst fierce competition, product innovation, as the core driving force for corporate longevity, has become an industry consensus. Based on this, Handa Industries continues to deepen the construction of its product innovation system—by systematically improving product technology content and functional experience, continuously consolidating the core value-added of products, and dynamically responding to the iterative and upgraded demand patterns of customers and consumers. This has established a closed-loop advantage in the market: "demand anticipation - innovation implementation - value delivery."

Fabric research and development

As the "Functional Knitted Fabric Product Development Base of the China National Textile and Apparel Council," "Functional Knitted Fabric Trend Research Center of the China National Textile and Apparel Council," and "Industry Industrial Design Center," Handa Industries has consistently focused on the R&D, innovation, and promotion of functional and differentiated knitted fabrics. By continuously researching new domestic and international raw materials, advanced weaving and finishing technologies, and integrating cutting-edge fashion trends with brand trends, Handa Industries continuously innovates and upgrades its products, resulting in the company holding 25 patents. At the same time, Handa Industries consistently adheres to the "Green Handa" corporate development strategy, effectively utilizing environmentally friendly, recycled, and sustainable materials in its R&D efforts to minimize negative environmental impacts from the very beginning.

With "technology, fashion, and green" as the core of its product research and development, Handa Industries has deeply laid out the "Heng" series of functional fabrics. It successfully developed approximately 250 fabrics throughout 2024, driving industry change with its innovative strength.

Heng Technology Focusing on functional breakthroughs, the company mainly promotes functional fabrics such as quick-drying, sun-proof and cool, warm, and sweat-free. Among them, the quick-drying series has a moisture absorption and quick-drying value far exceeding the national standard level 3, and the sweat-free series has also received positive feedback from various customers. It maximizes functionality and conquers consumers with data and experience; Heng Fashion series focuses on scenario design, nylon-spandex products, sports and leisure categories, and H-leggings yoga series, providing comfortable and fashionable experience for multiple scenarios such as home, office, leisure, and sports; Heng Green practices a sustainable development strategy, and uses bio-based, solution-dyed, paper yarn wool, recycled and other environmentally friendly products to help companies transform into green.

Innovative Environmental Protection: Handa Industries's Green Technology Practices

Scientific research confirms that microplastics have invaded human arteries, increasing the risk of heart disease, stroke, and all-cause mortality by 4.53 times. In response to this global environmental threat, Handa Industries, in collaboration with Donghua University, conducted technical research to transform used lunch boxes into ultra-fine polypropylene fibers, successfully developing the first low-carbon fabric made from recycled lunch boxes. This fabric reduces carbon emissions by 73% compared to virgin materials, not only creating a high-value recycling path for takeout lunch boxes but also enabling the production of quick-drying T-shirts and marathon capes, completing the closed-loop transformation from "plastic waste → eco-friendly fabric → practical apparel." This innovative achievement was also published in the prestigious journal Nature.

Cooperate with China Textile Information Center to hold a fabric designer technical salon

On December 20, Handa Industries and China Textile Information Center jointly held the "2024 Fabrics China Club Product Development Technology Salon". More than 60 of the top ten textile fabric designers and industry elites in China visited Handa and explored fabric innovation through workshop visits, product demonstrations, and theme sharing.

At the event, Tmall TMIC analyzed 25SS trends, industry experts shared insights on topics such as cycling culture and sustainable new materials, and Chen Baojian, Deputy Director of the National Textile Product Development Center, provided in-depth analysis of how technological innovation drives industrial upgrading. Handa Senior Vice President Jiang Yanhui presented the company's strategic layout and product requirements. Guests engaged in discussions with Handa's technical team on fabric design and development, deepening collaborative discussions through fireside chats.

This event not only showcases Handa's strength in production processes, quality control and innovative technologies, but also builds a high-end exchange platform for the industry, promoting the integration of textile fabric design and sustainable development concepts.

Ready-to-wear design

Handa Industries has always used innovative design and in-depth market insights as its dual engines to drive the company's transformation from OEM to ODM, building differentiated core advantages in industry competition and winning high market recognition.

At the forefront of the fashion industry, the company has ingeniously launched the MAX VIS series of products, a virtual brand for business (B2B). Based on three major styles: sportswear, fashion and leisure, and workwear, the series focuses on core categories such as crew neck sweaters, polo shirts, hoodies, pants, and zip-up shirts. The series deeply integrates functional needs with scenario-based application logic, continuously iterating its product R&D and design system. By organically integrating fabric technology with pattern aesthetics, the MAX VIS series not only achieves a value leap from "manufacturing" to "creation," but also provides customers with clothing solutions covering all scenarios through systematic design capabilities.

Sports style

1. Comprehensive training series:As MAX VIS's flagship product line, this collection is designed for high-intensity activities such as running, sweaty workouts, and professional training. The products not only focus on functionality, but also strike the perfect balance between style and comfort. From T-shirts and sweatshirts to training sweatpants, zip-up jackets, and pullovers, each item is meticulously designed and manufactured to meet the needs of athletes in various exercise situations. By deeply understanding the core needs of athletes, this collection not only provides competitive-level equipment support for professional athletes, but also offers practical and fashionable equipment options for fitness enthusiasts and team sports enthusiasts, making every exercise a pleasurable experience.

2.Fashion sports series:Designed specifically for yoga enthusiasts, this collection seamlessly integrates the needs of indoor yoga, light travel, jogging, commuting, and more. With lightness, comfort, and style at its core, this product line encompasses yoga pants, yoga tank tops, T-shirts, jackets, trousers, skirts, shorts, and more. Not only does it offer an exceptional wearing experience, but its diverse styles and colors add endless possibilities to everyday wear.

2. Fashionable and casual style

1. Fashion home series:Designed for young, fashionable and casual individuals, this collection focuses on youthful energy and the warmth and comfort of home. Key categories include girly home sets, casual home sets, and home skirts. Crafted from soft and comfortable fabrics, with meticulous attention to detail and tailoring, the collection strives to capture the youthful spirit of young women.

2. Comfortable and elegant series:We are dedicated to creating the epitome of mid- to high-end homewear, designed for consumers who value quality and style. Our core product categories include men's and women's casual homewear sets, base layers, underwear, and thermal products. We select high-quality fabrics, emphasizing comfort and breathability. Our designs are simple and elegant, with exquisite details that highlight the wearer's taste and style.

Workwear style

1. Classic and practical series:Designed for professionals who value quality and durability, this collection focuses on minimalist design and functionality, showcasing a professional and sophisticated work style. Key product categories include overalls, shirts, outerwear, and accessories. Made from stain-resistant and wear-resistant fabrics, these pieces emphasize sleek tailoring and practical details, such as multiple pockets and zipper closures, meeting the dual needs of professionals for both professionalism and comfort.

2、Fashion personality series:Designed for professionals seeking a unique style, this collection focuses on youthful, trendy design and incorporates workplace needs to create a series of professional yet stylish workwear. Key product categories include polo shirts, fashionable overalls, compression garments, base layers, shorts, and vests. Crafted from soft, breathable fabrics, the collection emphasizes playful design and refined details, such as unique color schemes and minimalist prints, helping professionals showcase their individuality and stylish style within their profession.

3.Comfortable and lightweight series:Designed for workers who need to be active for extended periods of time, this collection prioritizes comfort and functionality, providing a relaxed and effortless workplace experience. Key categories include loose shirts, sweaters, sportswear, and lightweight outerwear. Made from carefully selected breathable and durable fabrics, the collection emphasizes comfortable tailoring and natural aesthetics, ensuring workers experience both comfort and style in their daily workdays.

China National Textile and Apparel Council Fashion Trend Research Department empowers Handa product development

During the year, Handa Industries actively communicated with the Fashion Trend Research Department of the China National Textile and Apparel Council, conducting analytical training around the 2025 Spring/Summer and 2026 Autumn/Winter trends from three dimensions: consumer lifestyle, show style, and fabric trends. Combining Handa's R&D achievements with market demand, they clarified the full-chain design path of "trend foresight - product development - market implementation."

This event has injected cutting-edge design thinking into the company's R&D team, strengthened the "consumer-centric, trend-oriented" product development logic, and helped Handa's product iteration and value upgrade in the fields of fashion, technology, and green.

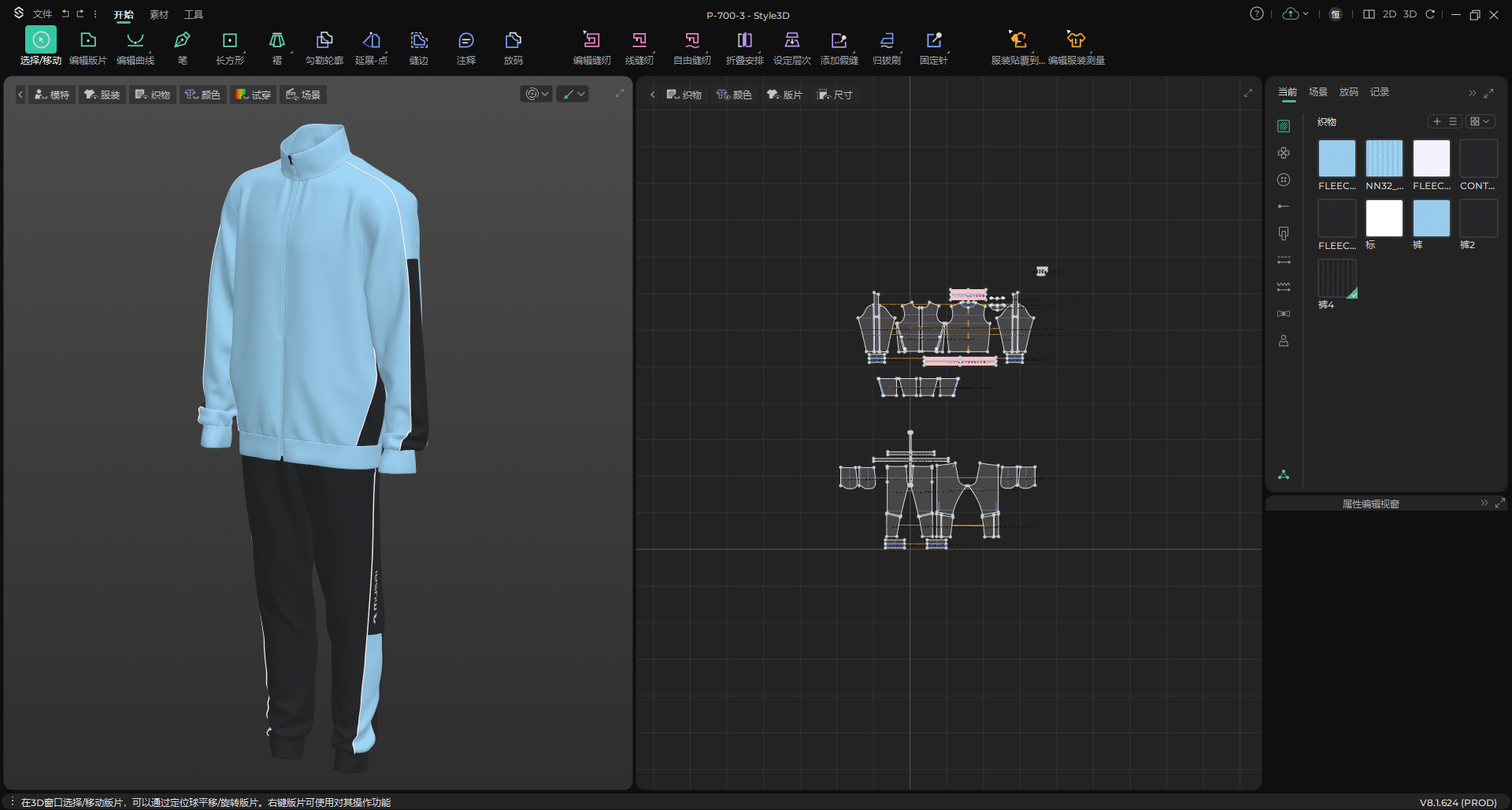

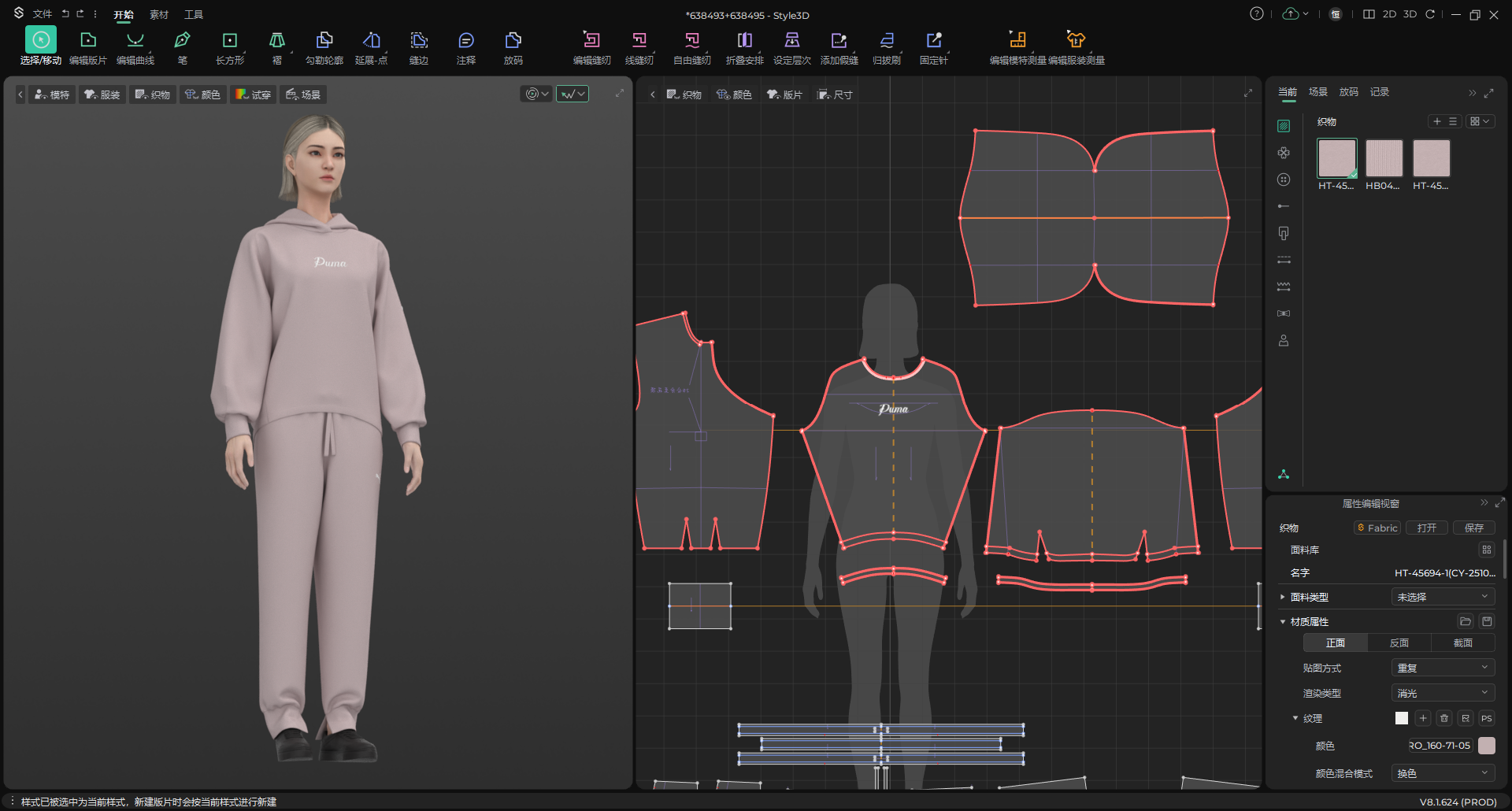

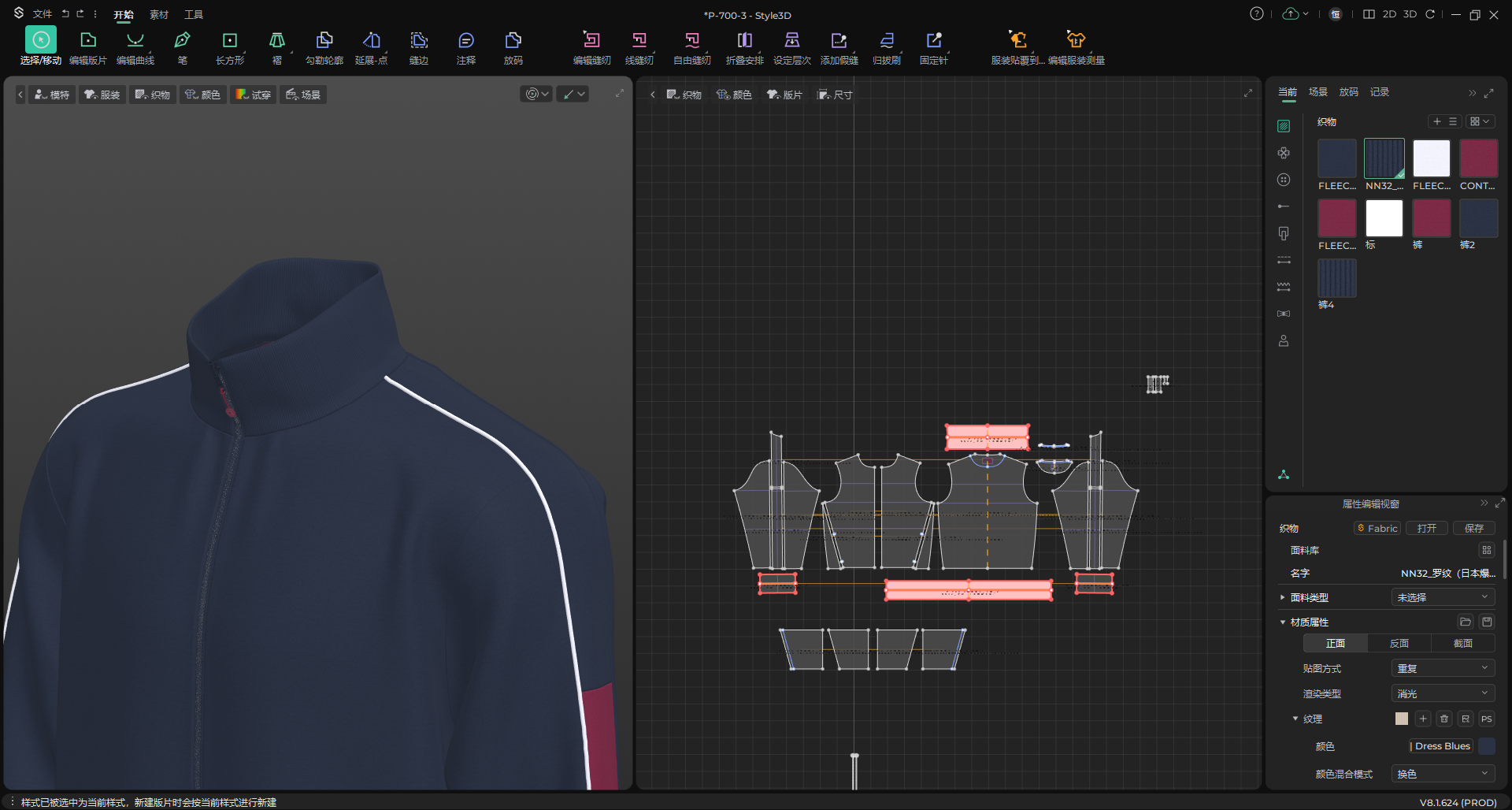

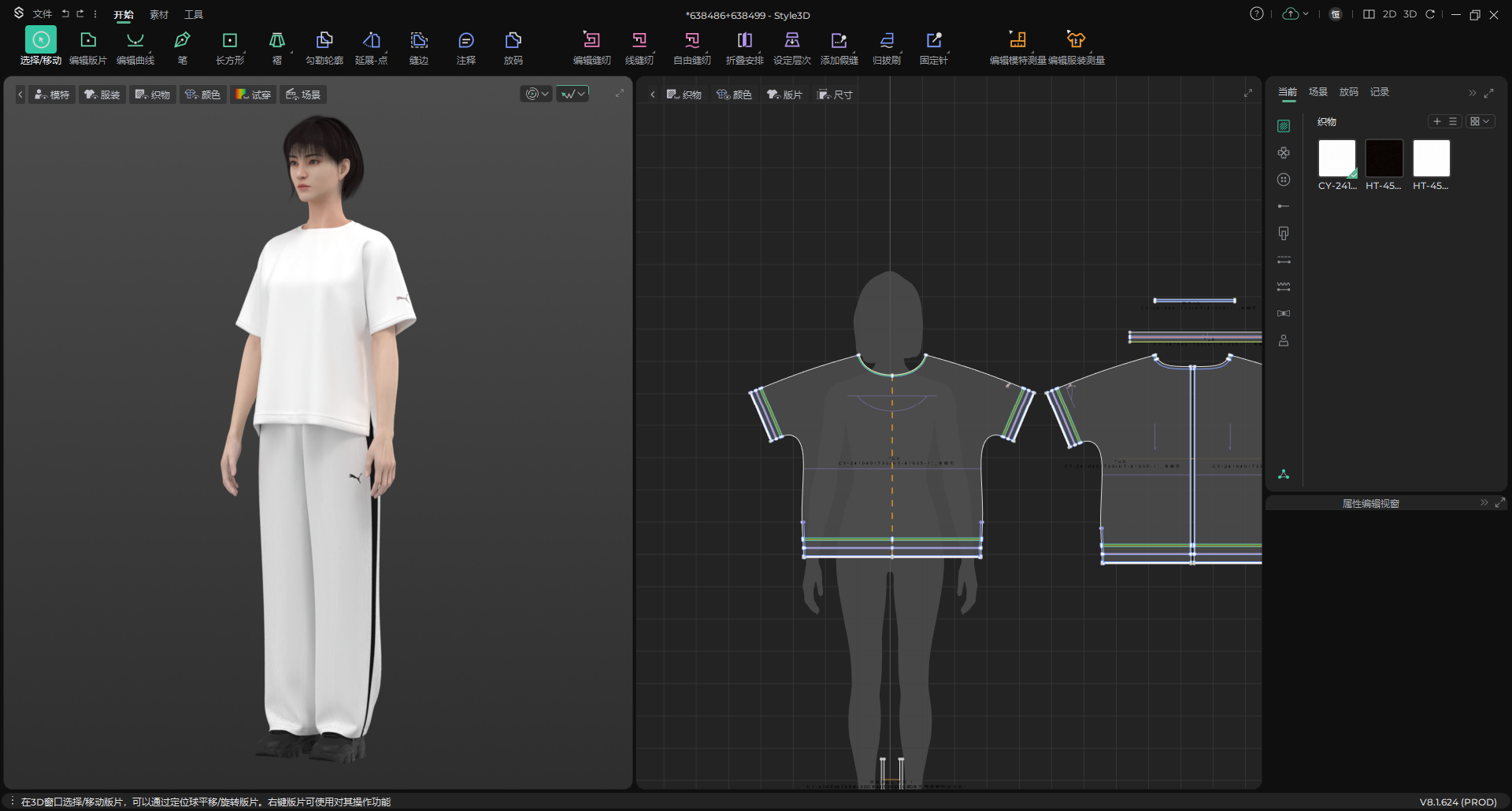

3D & AI Design

To proactively address resource and environmental challenges and reduce sample consumption and waste, Handa Industrieshas developed Handa 3D digital design software. This innovative tool significantly improves design efficiency and product performance prediction through features such as 3D modeling and proofing, 3D convenient revisions, 3D rendering simulation, and 3D content display.

3D modeling and proofing: Rapidly generate highly realistic samples in a virtual environment, shortening the R&D cycle.

3D convenient revision: Through AI intelligent analysis, you can easily adjust the design plan and improve R&D efficiency.

3D rendering simulation: Combined with AI algorithms, it accurately predicts the actual product effect, avoiding production waste and quality issues.

3D content display: Present products in a vivid way to enhance customer experience.

By 2024, Handa's apparel design department had designed over 1,500 products using 3D digital design technology, over 100 of which were adopted by renowned domestic and international sports brands (such as UBRAS, PUMA, ALPEN, and LUFIAN), generating over 50 million in sales. This technology not only helped the company reduce resource consumption in sample production but also enhanced product competitiveness through precise design and rapid iteration, providing strong support for the company's sustainable development strategy.

By integrating technological innovation with commercialization, Handa has not only achieved remarkable results in garment design but has also actively contributed to the industry's development towards efficiency, environmental protection, and intelligence. Going forward, we will continue to prioritize sustainable development, optimize our design processes, enhance product value, and create more surprises for consumers and partners.

Hold a new product launch conference

Handa Industries regularly holds spring/summer and autumn/winter new product launches, using 3D videos to interpret garment design concepts and 3D showrooms to showcase bio-based and other environmentally friendly fabrics. Combined with the application of AI technology, it showcases the fusion of fashion and sustainable development.

Participate in the China Textile Innovation Annual Conference to share industry innovation practices

In December, Handa Industries was invited to attend the 2024 China Textile Innovation Annual Conference. Focusing on the theme of "Insight into New Demands, Exploring New Paths", the conference shared Handa's practical experience in product development, management innovation, and environmental empowerment. The conference emphasized that the company explores intelligent manufacturing and green development paths by introducing advanced technologies, focusing on the research and development of functional fabrics such as antibacterial and quick-drying fabrics and new green and environmentally friendly fabrics, and improving market competitiveness through innovative products.