Innovation driving force

Sustainable technology empowerment

Handa Industries is promoting collaborative innovation and efficiency improvements across the entire industry chain by building a digital and intelligent development system. We are committed to sustainable product development, incorporating environmental protection concepts into every process, from raw materials to finished products. We continue to increase investment in technological innovation to overcome key industry bottlenecks. We also continuously optimize our service system to create more agile and comprehensive customer solutions. This systematic technology-enabled strategy is driving the company's steady progress toward green, intelligent, and high-end development, setting a new benchmark for sustainable development in the textile industry.

Building a digital intelligence ecosystem

With "digital intelligence integration and ecological win-win" as its core concept, Handa Industries is comprehensively promoting the construction of a digital intelligence ecosystem. By building a "cloud-edge-end" collaborative technical architecture and integrating new-generation information technologies such as the Internet of Things, big data, and artificial intelligence, we are creating digital intelligence solutions that span the entire R&D, business, production, and supply chain landscape. At the foundational layer, we deploy an industrial Internet platform to enable device interconnection and data collection; at the application layer, we develop digital tools such as intelligent scheduling, quality warnings, and energy consumption optimization; and at the ecological layer, we jointly build an industrial cloud platform with upstream and downstream partners to promote cloud-based sharing of design, manufacturing, and service resources. By establishing a unified data middle platform and business middle platform, we have broken down information silos and achieved digital collaboration across the entire chain, from raw materials to end products.

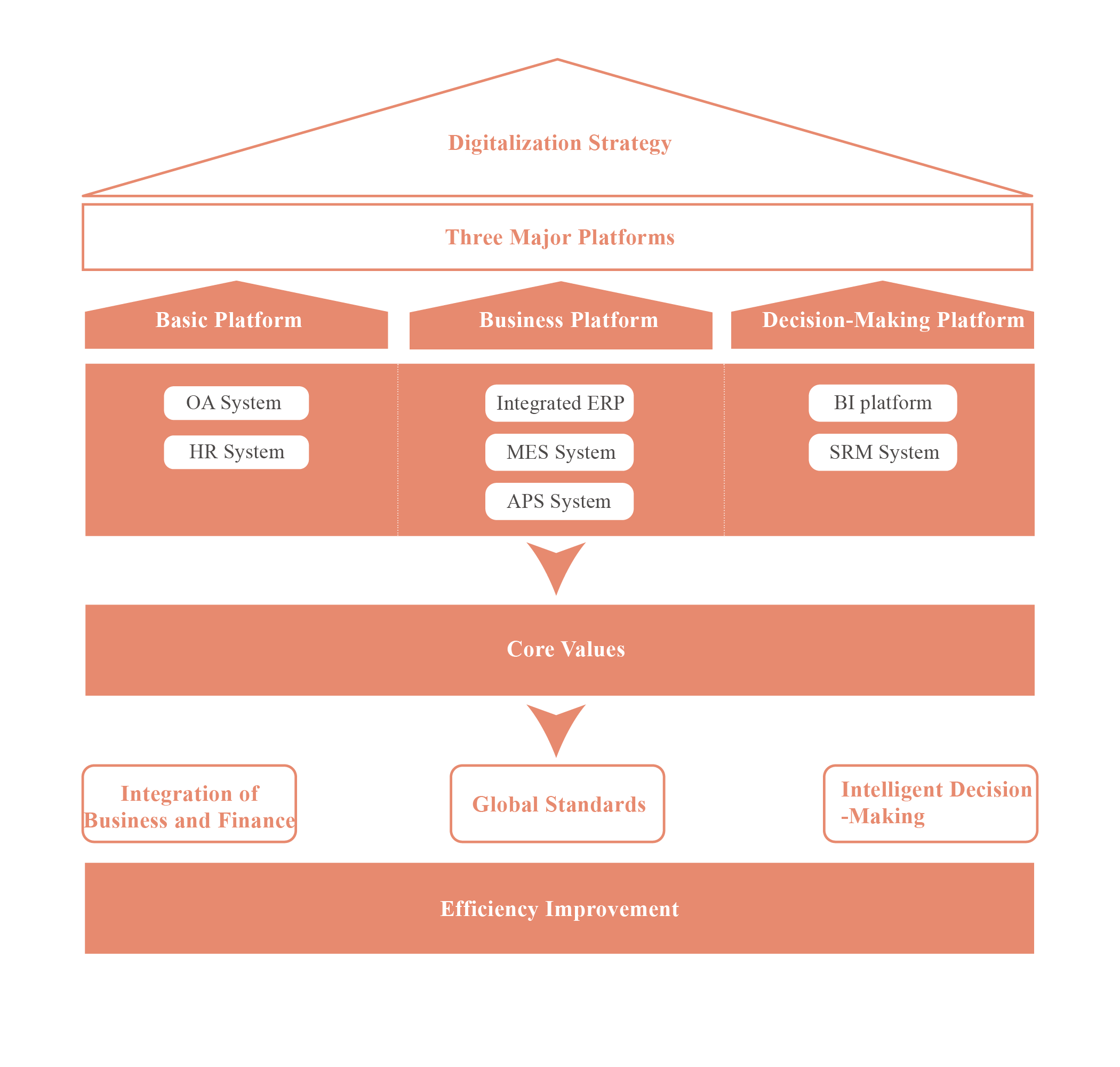

Digital transformation

Handa Industries continues to promote digital transformation and upgrading, and has built an intelligent management system cluster covering the entire business chain.“Global integrated digital platform”To achieve strategic goals, systematically solve the key pain points in Industries development.

At the basic platform level, the company has successfully launched the OA collaboration platform to achieve Nearly 100 Standardized management of administrative and business processes, efficiently handle 412,000 processes by 2024, reducing operating costs by 28%The HR management system comprehensively covers modules such as organizational structure, personnel management, attendance and salary, performance appraisal, and training and development, completing the digital reconstruction of the human resources system.

The business operations layer has focused on deploying from trading、Weaving、printing and dyeing to garment production Integrated ERP system effectively supports Inside External business expansion and supply chain collaboration will be fully launched in 2024; the MES system isFourLarge production bases are implemented in phases to promote the standardization of production and manufacturing processes; APS advanced scheduling system Also being implemented, which will enable precise online control of quality, cost and delivery time.

At the intelligent decision-making level, the BI data analysis platform has built a group data warehouse with more than 20 theme dashboards; the SRM supplier collaboration system also It will go online in 2024 to realize digital management of the entire life cycle of suppliers.

This system architecture effectively realizes three core values: through the deep connection between financial software and six major business systems, it completely breaks down the barriers of business and financial data; using the domestic system as a template, it is replicated in Myanmar and Egypt.,Bengal Overseas bases; integrating more than ten data sources such as finance, sales, production, and procurement to build a complete data intelligence decision-making system.

at present,Handa’s digital system has achieved remarkable results: business process efficiency has Significant improved, management reports have achieved real-time access and have made great strides. In the future, Handa will continue to improve this“Unified planning - step-by-step implementation - global promotion”The digital construction model provides solid support for the group's globalization strategy.

Advanced digital layout

In 2024, Handa Industries entered into strategic partnerships with two technology companies, launching group-level MES system development and SRM platform projects, respectively, to comprehensively advance the upgrade of smart factories and intelligent supply chains. The MES project focuses on data interconnection throughout the entire manufacturing process, aiming to achieve production visualization and intelligent management; the SRM project focuses on collaborative supply chain optimization, building an efficient procurement ecosystem through a digital platform.

Handa's digital transformation is moving from single-point technology application to collaborative innovation across the entire industry chain, accelerating the construction of a flexible and intelligent modern production system, and providing a practical model for the digital transformation of the apparel industry.

Obtained the "Jiangsu Province Five-Star Cloud Industries" certification

In September 2024, the Jiangsu Provincial Department of Industry and Information Technology announced the first batch of star-rated cloud-based Industries. Wuxi Hengbo Textile Co., Ltd., a subsidiary of Handa Industries, was awarded the title of "Five-Star Cloud-Based Industries" for its outstanding achievements in digital transformation. This certification, an authoritative assessment of industrial digitalization in Jiangsu Province, recognizes companies that excel in cloud computing applications and digital transformation.

AI+ layout

Handa Industries“AI+”Layout, in Industries management and product innovation have achieved significant results.. In terms of management and operations, AI translation tools enable barrier-free cross-border communication; digital human training improves the efficiency of employee skill development; and intelligent meeting assistants automatically generate minutes and extract key decisions.“Handalikechat”Internal Platform. The establishment and use of AI Knowledge Q&A, process optimization, and code development reminders, etc., comprehensively improve management efficiency.

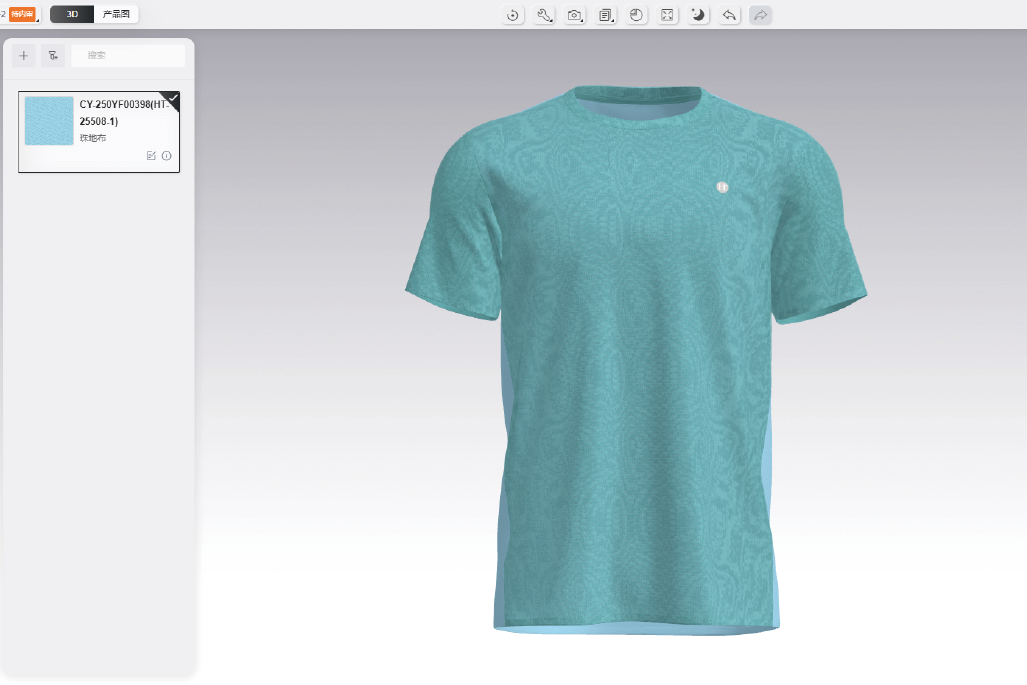

In the field of product development and design, we use cutting-edge AI technology to promote innovation and breakthroughs: AI image generation and rubbing technology accelerates the generation of design ideas; the virtual fitting system realizes 3D visual display of products; the intelligent modification tool supports rapid iteration of local design; the AI video production platform improves the efficiency of marketing content production. The in-depth application of this series of AI technologies not only shortened the product design cycle, but also create a new experience for customers through intelligent service upgrades, and continue to consolidate the company's digital leadership in the textile and apparel industry.

Handa Industries and China National Textile and Apparel Council jointly explore new paths for textile AI applications

During the year, Handa Industries and the China National Textile and Apparel Council (CNTEC) held discussions on the innovative applications and in-depth implementation of AI in the textile industry. Based on industry development trends and guided by collaborative innovation between industry, academia, and research, the two parties engaged in in-depth discussions on the practical application and breakthroughs of AI technology.

During the seminar, Handa Industries shared its AI achievements in product R&D and design, office process optimization, and other scenarios, while also addressing the challenges of technology integration and application expansion. The China National Textile and Apparel Council, drawing on cutting-edge industry trends, discussed solutions with Handa Industries. Both parties agreed that AI big data analysis can accurately capture market demand, predict trends, and optimize product design. They also promoted the in-depth application of AI automation technology in production and management, improving overall process efficiency. Furthermore, the two parties reached a consensus on a sustainable development model for the integration of AI and the textile industry, emphasizing the collaborative innovation between industry, academia, and research to overcome technological barriers and jointly explore new paths for AI to empower the textile industry.

Intelligent innovation

With the intelligent transformation of garment manufacturing as its core, Handa Industries will deepen its layout in all aspects by 2024, deeply integrate automation equipment and industrial Internet technologies, and strive to build a more complete and efficient full-process intelligent production system.

The company has vigorously introduced intelligent equipment such as automatic sewing equipment clusters, AI detection equipment, intelligent hanging systems, automatic sorting transmission lines and flexible handling AGV carts to achieve automated connection of the entire process of cutting, sewing, storage and packaging, and intelligent scheduling of logistics and transportation throughout the process, eliminating manual transportation losses in traditional production. While significantly improving production efficiency, it has also streamlined manpower input by more than 30%, providing hardware support for the "small order quick response" model.

At the production execution level, automated sewing equipment significantly improves sewing efficiency and quality consistency through automatic programming of process parameters. The equipment's built-in display panel and data transmission capabilities allow maintenance personnel to monitor operating status in real time, significantly improving the efficiency of single-machine production statistics. Workstation tablets equipped with facial recognition and skill binding systems ensure standardized operations. The intelligent hanging system, leveraging a B/S architecture and deep integration with the MES system, supports mixed-run production of multiple styles and sizes. New orders can be inserted into the production line in real time, significantly shortening production changeover time and reducing excess production.

The automated packaging line in the finishing phase integrates bionic robotic arms with rigid automation equipment. From automatic counting during needle detection to QR code recognition and precise robotic arm operation during packing, and finally to unmanned stacking, the entire process is highly automated, eliminating manual reporting errors and information transmission losses. AGVs automatically deliver materials along pre-set routes, significantly improving logistics efficiency and reducing safety risks in production operations.

From the iterative application of intelligent devices to the in-depth reconstruction of production systems, Handa Industries has always taken full-process automation and data interconnection as its core focus. While continuously strengthening its core competitiveness, it has also created a "Handa model" for the industry's intelligent transformation through the large-scale application of intelligent devices and independent innovation models.

Won the title of "Jiangsu Province 2024 Intelligent Manufacturing Workshop"

Handa Industries Actively responds to the "Smart Manufacturing 2025" strategy and promote factory transformation with digitalization and intelligence as the core. During the year, Handa Industries successfully selected into the list of Jiangsu Province's 2024 smart manufacturing workshops, this honor is an authoritative recognition of the company's continuous exploration in the fields of digital factory construction and smart manufacturing.

Obtained AAA certification for the integration of information and industrialization management system

Handa Industries successfully passed the assessment of the integration of information technology and industrialization management system and was awarded the AAA certification certificate, marking the company's breakthrough in the deep integration of informatization and industrialization.

Relying on the strategic leadership of the top management and the coordinated promotion of all departments, Handa Industries has built“Digital design and production integrated management and control capabilities”, achieving full-chain collaboration in design, production, and supply chain, and significantly improving value-benefit indicators in dimensions such as digital product design, production control, and operation management.

Passed the National Intelligent Manufacturing Capability Maturity Level 3 Assessment

Handa Industries successfully passed the National Intelligent Manufacturing Capability Maturity Level 3 Assessment (CMMM). Based on the national standards GB/T39116/39117, the assessment covered 15 key aspects of knitted garment process design and production. Through personnel interviews and on-site verification, it was confirmed that the company met the standardization requirements of intelligent manufacturing in terms of organizational strategy, data integration, and production operations.,This marks the company's leap from "standardization level" to "integration level" in the field of intelligent manufacturing.