sustainable development

In recent years, the world has advocated promoting ecological civilization. The concept of green development, "Clear waters and green mountains are invaluable assets", is becoming a new economic growth point and new driving force. Handa Industries actively responds to the call for green development, continues to carry out environmental protection projects, and strives to pursue better performance in energy conservation, emission reduction, waste management and other aspects. In addition, green environmental protection requirements will be integrated into the Company's product manufacturing and service, and a green ecology of common development between Companys and the environment and the community have been established.

Company is the creator of social wealth, but also a practitioner of social responsibility. We regard environmental protection as an important part of Handa Industries’s social responsibility, and our mission is to give back to the society. The company regards comprehensive and effective environmental protection, the lowest energy consumption, and the best product quality as its goals for sustainable development. The company establishes a complete set of environmental protection system, safety production system, energy management system and environmental protection emergency response plan to ensure that all links and procedures are standardized and dangerous factors are eliminated.

Sound Company environmental management mechanism, set up the environment management team and waste water treatment leading group, sewage treatment, management team, fully responsible for the management of Company environmental protection, sewage treatment, daily operation and independent monitoring work, reduce the pollution to the environment and harm, and coordinate with environment department work, understand the new environmental protection laws and regulations, the new requirements. All Companys' pollutant emissions have steadily reached the national and local emission standards, and the total amount of pollution emissions, comprehensive energy consumption per unit product, water consumption and total discharge of major pollutants have been effectively controlled to a leading level in the industry.

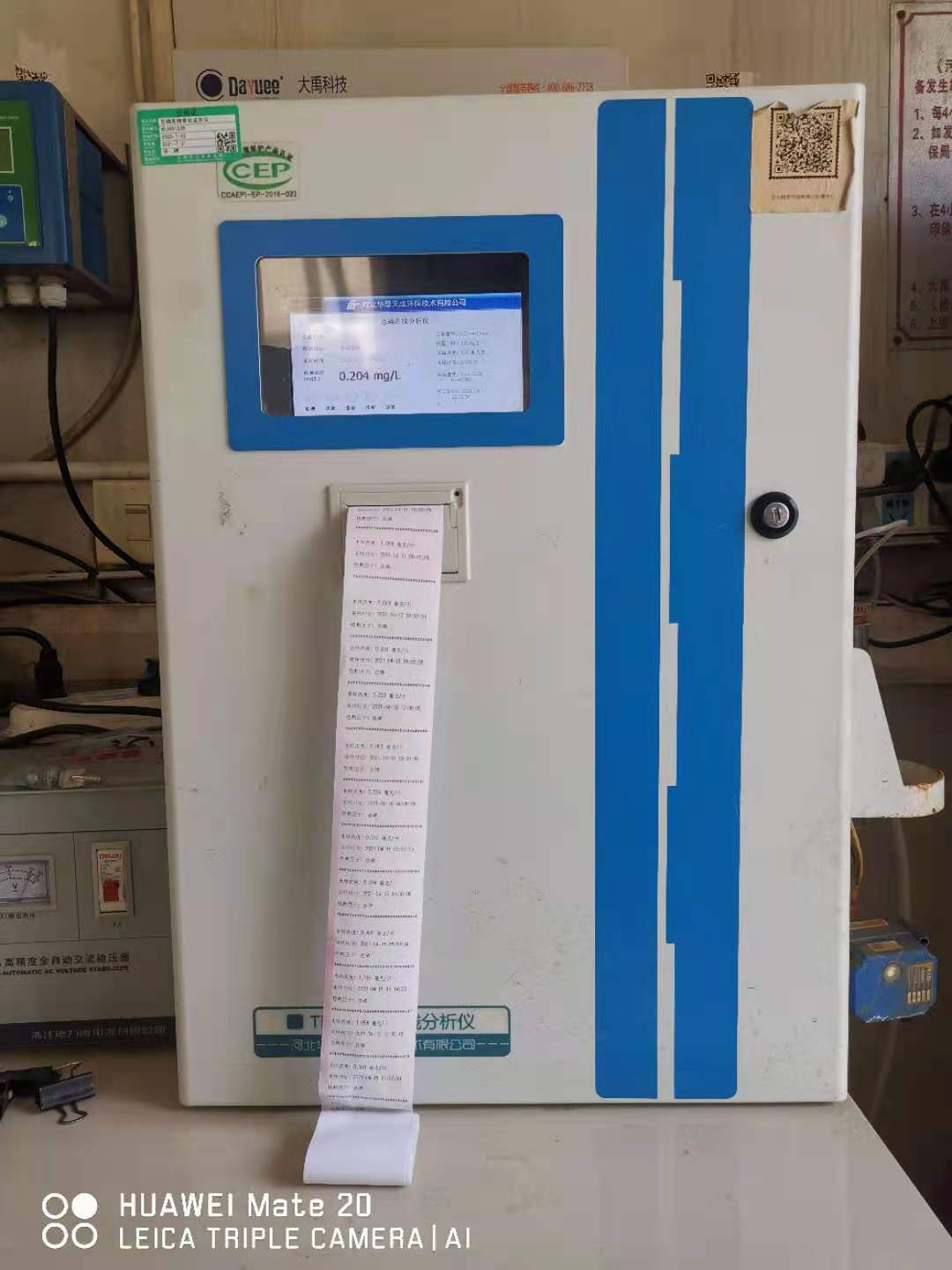

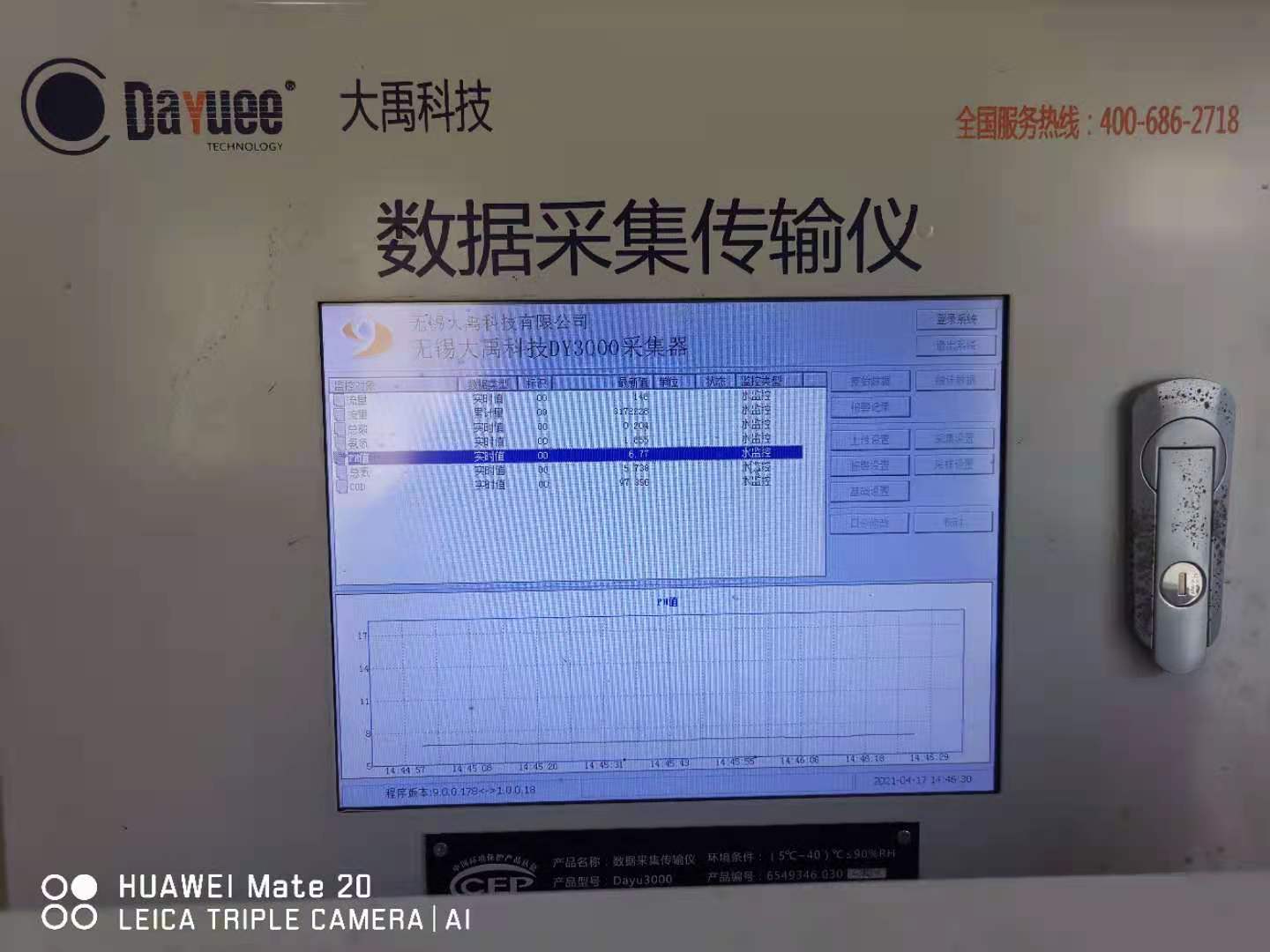

In accordance with the requirements of the environmental protection department, the company installs an online wastewater discharge monitoring system and a wastewater flow meter, and commissions a third-party qualified operating agency to perform operation, maintenance and regular calibration to ensure that the instrument is accurate and effective. The annual operating rate of environmental protection facilities is over 98%. The Company has got the national sewage permit and fills the execution report on time based on the requirement of the permit.

During the year, the company has made good achievements in energy conservation and emission reduction, environmental protection, clean production, safe production and circular economy. All kinds of pollution control facilities are in normal operation and meet the requirements of environmental protection. There have been no environmental pollution accidents, environmental disputes or reports on environmental protection.

In 2020, the company's main environmental protection work objectives have all been audited to meet the standards. During the year, the company prepared environmental risk assessment reports, emergency plans for environmental emergencies, water resources demonstration reports for water extraction projects, safety status assessment reports, emergency rescue plans for production safety accidents, and occupational health "three simultaneous" management productions.

2020 Major environmental goals

goals | standard | Management options | Progress or performance |

Sewage discharge meets the municipal sewage treatment takeover target | 1. 100% compliance rate of sewage treatment | 1. Strengthen management, improve sewage treatment regulations and operating procedures | 1. The sewage treatment facilities and monitoring facilities are perfect, with a normal operation rate of 100% and a sewage discharge rate of 100% |

Preventing chemical leakage | Safe storage and transportation without leakage | 1. Classified storage and mark making | The emergency plan for chemical leakage was formulated, and protection training was carried out. No chemical leakage accident occurred within the year |

General solid waste treatment | Comprehensive utilization rate 100% | 1. Waste auxiliary barrel and waste packaging bag are recycled by the supplier | All the waste additive drums and waste packaging bags are recycled by the supplier to the company, and the community regularly cleans up the household garbage in the company. The sludge is recycled by the environmental protection company and sent to the power plant for harmless incineration |

Hazardous waste disposal | Treatment rate 100% | Molding machine waste gas treatment produced waste oil Fuel packaging bag | Purchased and processed by qualified waste oil treatment Company acquisition processing |

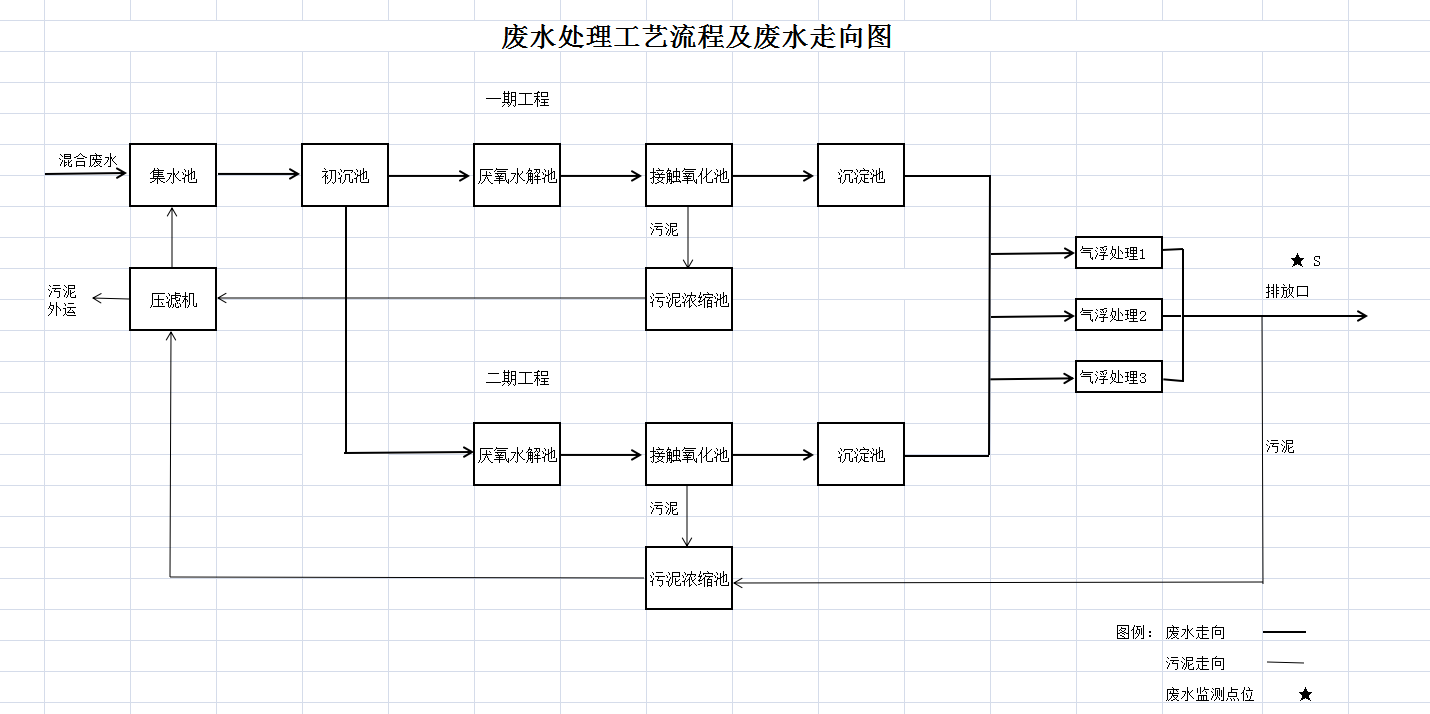

■Wastewater treatment process and wastewater trend diagram

In 2020, in accordance with environmental protection requirements, automatic online monitors for ammonia nitrogen, total phosphorus and total nitrogen will be added and run effectively.

In 2020, in order to meet environmental protection requirements and improve treatment efficiency, the Sewage Center invested more than 2.5 million yuan to build three sets of sewage treatment air flotation facilities, two sets of sludge filter press facilities, and corresponding auxiliary facilities to improve the effect and efficiency of sewage treatment. At the same time, more than 1 million yuan was invested to improve the fire emergency facilities of the printing and dyeing plant.

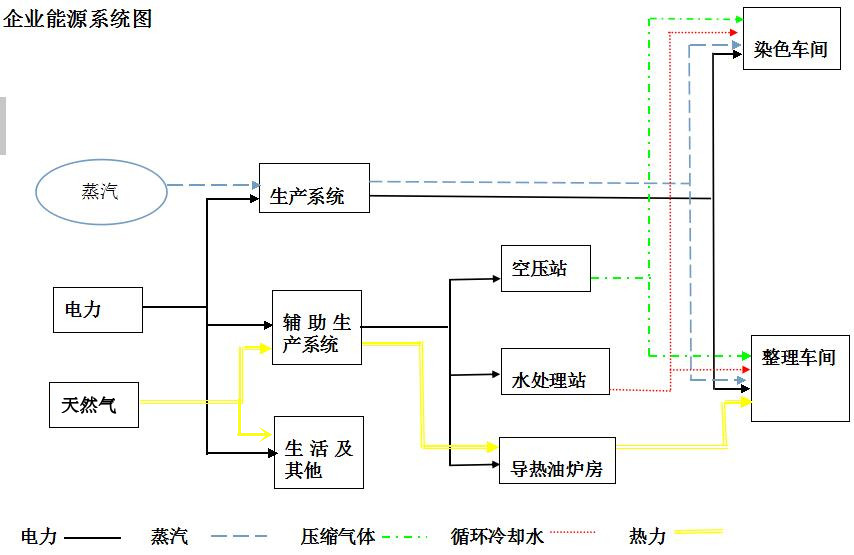

At present, the main business of the Company is knitting fabric and clothing manufacturing and dyeing and finishing processing, among which the dyeing and finishing processing is the main energy-using department, which belongs to the high-grade textile printing and dyeing and high-tech finishing and processing of light industry textile category in the Catalogue of Industries, Products and Technologies Encouraged by the State at Present, in line with the industrial policy. According to the Implementation Plan of Energy Saving and Low-carbon Action for Ten Thousand Companys issued by the National Development and Reform Commission and the Ministry of Industry and Information Technology and the energy saving target of Wuxi Municipal Economy and Information Committee for the 13th Five-Year Plan, the company shall: 1. Establish and improve the energy saving organization; 2. Reach implementing energy saving targets.

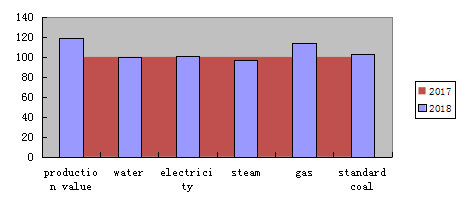

During the 13th Five-Year Plan period, the energy saving target has been achieved, and by 2020, 1867.60 tons of standard coal will be saved, with a completion rate of 109.86%.

Year | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | total |

Target (ton) Designation | —— | 340 | 340 | 340 | 340 | 340 | 1700 |

Actual completion of energy saving | —— | 602.58 | 475.3 | 220 | 315.09 | 254.7 | 1867.60 |

Overall energy efficiency per unit product | 1.122 | 1.056 | 1.008 | 0.987 | 0.957 | 0.931 | —— |

Future energy use and consumption of Companys:

During the period of the 13th Five-Year Plan, the Company switched to natural gas as fuel, replacing about 4,000 tons of raw coal fuel per year, basically accomplishing the energy saving goal of the 13th Five-Year Plan one year ahead of schedule.

Annual energy consumption(4.3.6;4.3.10;

energy | 2019 | 2020 | Increase/decrease |

Output Value(ten thousand yuan) | 108704.55 | 115865.88 | +6.59% |

Raw water (ton) | 898480 | 859719 | -4.50% |

Tap water (ton) | 153490 | 136466 | -12.47% |

electricity(c) | 16219720 | 15800670 | -2.65% |

Steam (ton) | 78425 | 65743 | -19.29% |

Natural gas (cubic meter) | 2965750 | 2859842 | -3.70% |

Standard coal (ton) | 13734 | 12293 | -12.22% |

Annual pollutant discharge

pollutant | 2019 | 2020 | Increase/decrease |

Sewage (ton) | 999370 | 946375 | -5.59% |

COD(ton) | 49.87 | 47.31 | -5.59% |

The total amount of recycled water in 2020 is about 258,750 tons, occupying about 25.9% of the total water. Compared with 2019, the energy consumption per unit output value has dropped by 12.22%.

In 2020, the total amount of Company sewage charges is 4,853,780 yuan.

During the reporting period, no environmental pollution accidents occurred, no complaints about environmental pollution were received, and no legal sanctions were imposed for violating relevant environmental laws and regulations.